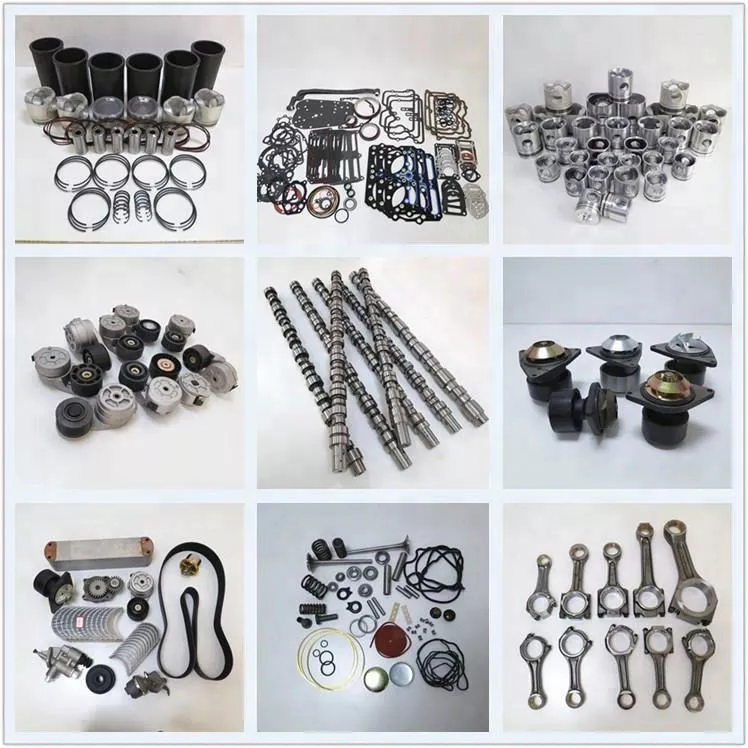

Product Description

Water Pump Drive Belt Pulley Tensioner

| Brand | FREY |

| Market Type | Aftermarket |

| Price Term | EXW, FOB HangZhou/HangZhou |

| Payment | T/T, Paypal, West Union, L/C, Cash, etc |

| Quality | Produced according to the OE Parts |

| Delivery Time | 1-5days for stock items; 15-30days for the items need produced. |

| Shippment | DHL, Fedex,TNT,UPS, By Sea, By Air. |

| Warranty | 1 Year |

| Packing | Frey Brand, Customer Brand, Neutral Packing |

| Samples | Charge |

Specifications

1.Supply to Sounth America, Europe, Amercia, Asia

2.Certificate: ISO 9001, SGS, TUV

3.Professional Perfomance Auto parts supplier

4.Delivery Time:2-3 days if in stock; 5-15 days if out of stock

HangZhou CZPT Auto Parts Company

FREY brand was founded in 2005. Our main products focuses on serving the German car system. The products are suitable for Mercedes-Benz, BMW and other luxury car brands.

With first-class scientific research team and perfect quality control system, CZPT has covered more than 100 countries and regions in the world, adopted international advanced quality management system in quality, strict standard process control, and followed the rigorous attitude of German automotive technology. In raw material procurement, production, processing, assembly and finished products, every aspect of the process is transparent to the outside world.

Frey has always pursued the idea of internationalization. In Germany, the United Kingdom, France, Italy, Russia, Poland, Turkey, the United States and other more than 30 countries and regions, there are FREY’s brand intellectual property, but also to synchronize the management system of German spare parts companies And brand requirements, bring high-quality brand experience and distinguished service experience to customers in the Chinese market.

| Car Make: | Mercedes Benz |

|---|---|

| Car Model: | Sprinter |

| Engine Type: | Om651 M272 M273 |

| Component: | Radiator |

| Body Material: | Iron |

| Cold Style: | Water-cooled |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

Can you explain the benefits of using drive belt tensioners in preventing slippage and optimizing power transmission in machinery and vehicles?

Using drive belt tensioners provides several benefits in preventing slippage and optimizing power transmission in machinery and vehicles. Tensioners play a critical role in maintaining proper belt tension, ensuring efficient power transfer, and maximizing the performance of belt-driven systems. Here’s a detailed explanation of the benefits of using drive belt tensioners:

- Preventing Slippage:

- Optimizing Power Transmission:

- Load Distribution:

- Reduced Maintenance:

- Versatility and Adaptability:

One of the primary benefits of drive belt tensioners is their ability to prevent slippage between the belt and the pulleys. Slippage can occur when the belt loses traction with the pulleys due to insufficient tension or excessive loads. Tensioners apply the correct amount of tension to keep the belt tightly engaged with the pulleys, preventing slippage. By maintaining proper belt tension, tensioners ensure reliable power transmission, minimize energy losses, and prevent performance degradation caused by slippage.

Drive belt tensioners optimize power transmission by ensuring efficient transfer of rotational energy from the driving pulley to the driven components. Tensioners maintain the proper tension in the belt, which allows for optimal power transfer without energy losses due to slippage. By keeping the belt under the correct tension, tensioners enable the belt-driven system to operate at its designed speeds and deliver the intended performance. This optimal power transmission contributes to improved overall efficiency, reduced energy consumption, and enhanced productivity in machinery and vehicles.

Tensioners help distribute the load evenly across the belt and the pulleys, minimizing localized stress and wear. Uneven loading can lead to premature wear, belt damage, and reduced system reliability. Drive belt tensioners maintain consistent tension throughout the operating range, ensuring that the load is evenly distributed across the belt’s width and the pulleys’ surfaces. This even load distribution promotes uniform wear, extends the lifespan of the belt, and reduces the risk of belt failure or damage caused by excessive localized stresses.

Proper tensioning provided by drive belt tensioners reduces the need for frequent maintenance and adjustments. Tensioners help maintain the optimal tension, minimizing belt wear and elongation. By preventing slippage and maintaining consistent tension, tensioners reduce the risk of unexpected belt failures and the need for frequent re-tensioning. This results in reduced maintenance requirements, increased system uptime, and improved overall reliability and productivity in machinery and vehicles.

Drive belt tensioners offer versatility and adaptability in various applications. Tensioners are available in different designs and configurations to accommodate different belt types, sizes, and operating conditions. They can be adjusted to suit specific tension requirements or to compensate for changes in belt length due to wear or temperature variations. This versatility allows tensioners to be used in a wide range of machinery and vehicles, providing the necessary tensioning force and adaptability to optimize power transmission and prevent slippage in diverse operating environments.

In summary, using drive belt tensioners in machinery and vehicles provides several benefits in preventing slippage and optimizing power transmission. Tensioners prevent slippage by maintaining proper belt tension, ensuring reliable power transfer, and minimizing energy losses. They optimize power transmission by enabling efficient transfer of rotational energy and maximizing the performance of belt-driven systems. Additionally, tensioners promote even load distribution, reduce maintenance requirements, and offer versatility and adaptability for different applications. By utilizing drive belt tensioners, machinery and vehicles can achieve improved efficiency, reliability, and overall performance.

Can drive belt tensioners be customized or modified to suit specific automotive or industrial needs?

Drive belt tensioners can be customized or modified to suit specific automotive or industrial needs. Manufacturers of tensioners offer various options and configurations to accommodate different applications and requirements. Here’s a detailed explanation of how drive belt tensioners can be customized or modified:

- Tensioner Design:

- Tensioner Size and Mounting:

- Tensioner Load Capacity:

- Additional Features:

Drive belt tensioners come in different designs to meet specific needs. Manufacturers offer a range of tensioner designs, such as spring-loaded tensioners, hydraulic tensioners, and automatic tensioners. These designs can be customized based on the specific requirements of the automotive or industrial application. For example, some applications may require tensioners with higher load-bearing capacity or increased resistance to environmental factors like dust, moisture, or extreme temperatures. Manufacturers can modify the tensioner design to incorporate features that enhance durability, performance, and reliability in these challenging conditions.

Drive belt tensioners are available in various sizes to accommodate different belt widths and pulley configurations. Manufacturers provide tensioners in different dimensions, allowing customization based on the specific dimensions of the belt and pulley system. Additionally, tensioners can be modified to suit different mounting requirements. Some applications may require tensioners with specific mounting brackets or orientations to fit within the available space or align with other components. Manufacturers can customize the tensioner’s size, shape, and mounting features to ensure compatibility and ease of installation in the target application.

The load capacity of a drive belt tensioner is an essential consideration for certain applications. Industrial or heavy-duty automotive applications may require tensioners with higher load capacity to withstand increased belt tensions or accommodate larger belt-driven systems. Manufacturers can customize tensioners to meet these requirements by using stronger materials, incorporating reinforced components, or optimizing the tensioner’s internal structure to handle higher loads. By customizing the tensioner’s load capacity, it can reliably handle the specific demands of the application and ensure long-term performance.

Drive belt tensioners can be customized with additional features to enhance their functionality or address specific needs. For example, manufacturers may offer tensioners with built-in dampers to reduce vibrations or noise in certain applications. Some tensioners may have adjustable arms or pulleys to provide fine-tuning of the belt tension. Manufacturers can also customize tensioners to incorporate special coatings or materials that improve resistance to corrosion, abrasion, or other environmental factors. These additional features can be tailored to suit the specific automotive or industrial needs, providing enhanced performance and longevity.

In summary, drive belt tensioners can be customized or modified to suit specific automotive or industrial needs. Manufacturers offer various options for tensioner design, size, mounting, load capacity, and additional features. By customizing tensioners, they can be optimized to meet the requirements of different applications, ensuring compatibility, reliability, and enhanced performance. When selecting or modifying drive belt tensioners, it is essential to consider the specific needs of the application and consult with manufacturers or experts to determine the most suitable customization options.

What is a drive belt tensioner, and how does it function in automotive and industrial applications?

A drive belt tensioner is a mechanical component used in automotive and industrial applications to maintain proper tension in the drive belt system. It is designed to ensure that the belt remains tight and properly engaged with the pulleys, allowing for efficient power transmission. Here’s a detailed explanation of what a drive belt tensioner is and how it functions:

- Definition and Components:

- Function in Automotive Applications:

- Function in Industrial Applications:

- Functioning Mechanism:

- Benefits and Importance:

A drive belt tensioner, also known as a belt tensioner or a serpentine belt tensioner, is typically a spring-loaded or hydraulic mechanism that exerts constant tension on the drive belt. It consists of several components, including a tensioner pulley, an arm or bracket, a spring or hydraulic cylinder, and a pivot point. The tensioner pulley is responsible for applying tension to the belt, while the arm or bracket holds the pulley in place. The spring or hydraulic cylinder provides the force necessary to maintain tension, and the pivot point allows for movement and adjustment.

In automotive applications, drive belt tensioners are commonly used in the serpentine belt system. The serpentine belt is a single, long belt that drives various engine accessories, such as the alternator, power steering pump, air conditioning compressor, and water pump. The tensioner ensures that the serpentine belt remains properly tensioned, preventing slippage and ensuring efficient power transfer to these accessories. It compensates for belt stretch, wear, and load variations, maintaining consistent tension and optimizing the performance of the engine accessories.

In industrial applications, drive belt tensioners are employed in various belt drive systems. These systems may include multiple belts, such as V-belts or timing belts, driving different components in machinery or equipment. The tensioner’s role is to maintain proper tension in each belt, ensuring reliable power transmission and preventing slippage. It adapts to load variations, compensates for belt stretch and wear, and helps distribute the load evenly among the belts. By maintaining optimal tension, drive belt tensioners enhance the overall efficiency, reliability, and lifespan of the belt drive systems in industrial applications.

The functioning of a drive belt tensioner depends on its specific design, which can vary depending on the application and the type of tensioner used. In general, tensioners utilize the force generated by a spring or hydraulic cylinder to exert tension on the belt. The tensioner is typically mounted on an adjustable arm or bracket, allowing for movement and adjustment to maintain the desired tension. As the belt stretches or wears over time, the tensioner compensates by applying additional tension to keep the belt properly engaged with the pulleys. Some tensioners incorporate automatic self-adjustment mechanisms, while others may require manual adjustment or periodic inspection to ensure proper tension.

Drive belt tensioners offer several benefits and play a crucial role in automotive and industrial applications. They prevent slippage, optimize power transmission, and maintain consistent tension in the belt drive systems. By compensating for belt stretch, wear, and load variations, tensioners ensure reliable and efficient operation of the driven components. They reduce the risk of belt failure, minimize wear and fatigue, and extend the lifespan of the belts. Proper tensioning provided by drive belt tensioners enhances overall system performance, reduces maintenance requirements, and increases the reliability and longevity of the belt drive systems.

In summary, a drive belt tensioner is a mechanical component that maintains proper tension in the drive belt system. It functions by applying tension to the belt using a pulley, spring, or hydraulic cylinder. In automotive applications, tensioners optimize power transmission in the serpentine belt system, while in industrial applications, they ensure reliable power transfer in various belt drive systems. By compensating for belt stretch, wear, and load variations, drive belt tensioners enhance efficiency, reduce wear, and extend the lifespan of the belts, contributing to the overall performance and reliability of automotive and industrial machinery.

editor by CX 2023-12-04

China Standard Water Pump Drive Belt Pulley Tensioner 6112340293 with Best Sales

Product Description

Water Pump Drive Belt Pulley Tensioner

| Brand | FREY |

| Market Type | Aftermarket |

| Price Term | EXW, FOB HangZhou/HangZhou |

| Payment | T/T, Paypal, West Union, L/C, Cash, etc |

| Quality | Produced according to the OE Parts |

| Delivery Time | 1-5days for stock items; 15-30days for the items need produced. |

| Shippment | DHL, Fedex,TNT,UPS, By Sea, By Air. |

| Warranty | 1 Year |

| Packing | Frey Brand, Customer Brand, Neutral Packing |

| Samples | Charge |

Specifications

1.Supply to Sounth America, Europe, Amercia, Asia

2.Certificate: ISO 9001, SGS, TUV

3.Professional Perfomance Auto parts supplier

4.Delivery Time:2-3 days if in stock; 5-15 days if out of stock

HangZhou CZPT Auto Parts Company

FREY brand was founded in 2005. Our main products focuses on serving the German car system. The products are suitable for Mercedes-Benz, BMW and other luxury car brands.

With first-class scientific research team and perfect quality control system, CZPT has covered more than 100 countries and regions in the world, adopted international advanced quality management system in quality, strict standard process control, and followed the rigorous attitude of German automotive technology. In raw material procurement, production, processing, assembly and finished products, every aspect of the process is transparent to the outside world.

Frey has always pursued the idea of internationalization. In Germany, the United Kingdom, France, Italy, Russia, Poland, Turkey, the United States and other more than 30 countries and regions, there are FREY’s brand intellectual property, but also to synchronize the management system of German spare parts companies And brand requirements, bring high-quality brand experience and distinguished service experience to customers in the Chinese market.

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.