Solution Description

|

Industrial Vacuum pump VRD-thirty/ vacuum pump/ vacuum pumping

Connected Goods |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Our Business | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ever-electricity Team professional in generating all sorts of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear pace reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, car gearboxes, pto shafts, particular reducer & relevant equipment elements and other associated products, sprockets, hydraulic technique, vacuum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars lower backlash worm reducers and so on. furthermore, we can produce tailored variators, geared motors, electrical motors and other hydraulic merchandise according to customers’ drawings. We gives a dependable grantee for the product’ s high quality by innovative inspection and testing products. specialist specialized group, exquisite processing engineering and stringent management program. In recent many years, the firm has been developing speedily by its prosperous encounter in creation, advanced management technique, standardized administration system, strong technical pressure. We usually adhere the idea of survival by top quality, and development by innovation in science and engineering. Our Team is ready to perform with you hand in hand and create brilliance together! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Substance obtainable Lower carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless metal. Can be tailored relating to consumer demands. |

Surface therapy Blacking, galvanization, chroming, electrophoresis, shade portray, …

|

Heat therapy Substantial frequency quenching heat remedy, hardened enamel, carbonizing, nitride, … |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certifications | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FAQ:

Q: Are you investing firm or company ? Q: Do you give samples ? is it free of charge or added ? Q: How extended is your supply time ? What is your phrases of payment ? Q: What is the actual MOQ or value for your item ? If you have another issue, please truly feel free to make contact with us. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Packing & Shipping and delivery | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

US $10-999 / Piece | |

10 Pieces (Min. Order) |

###

| Oil or Not: | Custom |

|---|---|

| Structure: | Custom |

| Exhauster Method: | Custom |

| Vacuum Degree: | Vacuum |

| Work Function: | Custom |

| Working Conditions: | Custom |

###

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Item No. |

VRD-16 |

VRD-24 |

VRD-30 |

VRD-40 |

VRD-60 |

|||

|

Displacement speed m3/h (cfm) |

50 Hz |

16(9.4) |

24(14.1) |

30(17.6) |

40(23.5) |

60(35.3) |

||

|

60 Hz |

19.2(11.3) |

28.8(16.9) |

36(21.2) |

48(28.2) |

72(42.3) |

|||

|

Ultimate Pressure (mbar) |

Without Gas Ballast |

Partial Pressure |

5×10-4 |

5×10-4 |

5×10-4 |

5×10-4 |

5×10-4 |

|

|

Total Pressure |

5×10-3 |

5×10-3 |

5×10-3 |

5×10-3 |

5×10-3 |

|||

|

With Gas Ballast |

Total Pressure |

8×10-3 |

8×10-3 |

8×10-3 |

8×10-3 |

8×10-3 |

||

|

Power Supply |

Single/3-ph |

3-ph |

3-ph |

3-ph |

3-ph |

|||

|

Motor power (KW)

|

0.75/0.55 (single/3-ph) |

0.75 (3-ph) |

1.1 (3-ph) |

1.5 (3-ph) |

2.2 (3-ph) |

|||

|

Inlet and outlet port DN(mm) |

25 KF |

25KF |

25KF |

40KF |

40KF |

|||

|

Oil Capacity (L) |

0.9~1.5 |

1.3~2.0 |

1.3~2.0 |

1.8~3.0 |

1.8~3.0 |

|||

|

Motor speed (rpm) |

50 Hz |

1440 |

1440 |

1440 |

1440 |

1440 |

||

|

60 Hz |

1750 |

1750 |

1750 |

1750 |

1750 |

|||

|

Ambient temperature () |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

|||

|

Noise level dB(A) |

≤56 |

≤56 |

≤56 |

≤59 |

≤59 |

|||

|

Type of Protection (IP) |

44 |

44 |

44 |

44 |

44 |

|||

|

Weight (kg) |

30 |

35 |

43 |

65 |

||||

|

US $10-999 / Piece | |

10 Pieces (Min. Order) |

###

| Oil or Not: | Custom |

|---|---|

| Structure: | Custom |

| Exhauster Method: | Custom |

| Vacuum Degree: | Vacuum |

| Work Function: | Custom |

| Working Conditions: | Custom |

###

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Item No. |

VRD-16 |

VRD-24 |

VRD-30 |

VRD-40 |

VRD-60 |

|||

|

Displacement speed m3/h (cfm) |

50 Hz |

16(9.4) |

24(14.1) |

30(17.6) |

40(23.5) |

60(35.3) |

||

|

60 Hz |

19.2(11.3) |

28.8(16.9) |

36(21.2) |

48(28.2) |

72(42.3) |

|||

|

Ultimate Pressure (mbar) |

Without Gas Ballast |

Partial Pressure |

5×10-4 |

5×10-4 |

5×10-4 |

5×10-4 |

5×10-4 |

|

|

Total Pressure |

5×10-3 |

5×10-3 |

5×10-3 |

5×10-3 |

5×10-3 |

|||

|

With Gas Ballast |

Total Pressure |

8×10-3 |

8×10-3 |

8×10-3 |

8×10-3 |

8×10-3 |

||

|

Power Supply |

Single/3-ph |

3-ph |

3-ph |

3-ph |

3-ph |

|||

|

Motor power (KW)

|

0.75/0.55 (single/3-ph) |

0.75 (3-ph) |

1.1 (3-ph) |

1.5 (3-ph) |

2.2 (3-ph) |

|||

|

Inlet and outlet port DN(mm) |

25 KF |

25KF |

25KF |

40KF |

40KF |

|||

|

Oil Capacity (L) |

0.9~1.5 |

1.3~2.0 |

1.3~2.0 |

1.8~3.0 |

1.8~3.0 |

|||

|

Motor speed (rpm) |

50 Hz |

1440 |

1440 |

1440 |

1440 |

1440 |

||

|

60 Hz |

1750 |

1750 |

1750 |

1750 |

1750 |

|||

|

Ambient temperature () |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

|||

|

Noise level dB(A) |

≤56 |

≤56 |

≤56 |

≤59 |

≤59 |

|||

|

Type of Protection (IP) |

44 |

44 |

44 |

44 |

44 |

|||

|

Weight (kg) |

30 |

35 |

43 |

65 |

||||

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations

There are several safety considerations to consider when using pulleys. The first is Secure Workload (SWL). This value is a general guideline for the maximum weight a pulley can safely handle. It varies according to the height and angle of the pulley. Besides SWL, there are some other factors to consider. Consider each one before deciding on the pulley that best suits your needs.

Another safety consideration is the weight of the load. Since the highs of the pulley are higher than the lows, it doubles in weight. The weight of the high point should not exceed 4 kN. The safety factor is calculated by multiplying the strength of the pulley by the weight of the load. Secondary COD has a safety factor of 10:1 and bulletproof primary anchors should be used with pulleys.

If using a chain hoist, you must be trained in the appropriate type of lifting. It is important not to hang on the top hooks of the structure, nor to overload or rig the hooks with multiple slings. You should also avoid corroded or damaged chains, as they can cause the crane to jam or overload. A worn chain can even cause the load to drop.

Components of a pulley system

Proper design of the pulley system can increase the life of the cables and pulleys. Larger diameter cables should be selected as they are more durable than smaller diameter cables. The cables should also be supported in the pulley grooves. The pulley must be designed to be compatible with the cable and its lubrication should be optimal. Proper lubrication of cables and pulleys will ensure maximum durability and longevity.

The first type of pulley is called a fast pulley. These pulleys are used for quick start and stop of the machine. These pulleys are usually mounted in pairs on the countershaft of the machine. One pulley is tightly mounted on the machine shaft, while the other pulley is fitted with a free-spinning mechanism. When the machine is running, the belt is mounted on the tensioner pulley, and when it is stopped, the belt slides on the independent pulley.

Composite pulley sets reduce the overall effort required by reducing the size of the pulley. These are usually attributed to Archimedes. Flat pulleys are often used in flat belt driven transmission systems. These are used in high-speed, low-power applications. Flat pulley idlers are also used on the back of traditional V-belts.

editor by czh 2022-11-26

China Custom 2020 Industrial construction centrifugal clutch dual pulley 36.5mm bore for 60HP engine pulley assembly

Applicable Industries: Construction works

Type: V-BELT

Material: Steel

Bore size: 36.5mm

Pulley diameter: 126mm

clutch body diameter: 170mm

Belt type: 2B

Engine: up to 60HP

Packaging Details: 2571 Industrial construction centrifugal clutch dual pulley 36.5mm bore for 60HP engine 1) carton with pallets 2) customized color box with pallets

Port: HangZhou or ZheJiang Port

2571 Industrial construction centrifugal clutch dual pulley 36.5mm bore for 60HP engine Detailed Images Related ProductsPacking&Shipping Company IntroductionWelcome to the JinYi Machinery co., LTD. website we look forward to serving your parts needs.Founded in 2571, we started with just 4 people and an idea , go kart parts came first , and since then , we have expanded toeverything in different Vehicle parts ,such as scooter parts , ATV parts , UTV parts , bicycle parts , golf cart parts ,customized parts etc.We’ 1.6m high efficiency tractor pto sickle bar mowers for sale re young , but we’re efficient !Our company is not big , but our operating costs are low , which can help you save much purchase cost .We ship all day , every day ! We know you want to get your projects together and your equipment repaired ASAP , we try our best tokeep stock on our most popular items and keep having enough raw material in warehouse , which can help wait time shorter forspecial order items .Our Company have professional engineers team and 24 hours online customer service .Please take some time to browse through the website, If any items you can not find on our website , please not hesitate to contactwith us by email or phone We appreciate our customers so much ! it is because of you that we we are expanding every year .Always ready to serve you ! Agricultural hay mower with tractor grass cutter disc mower JinYi TEAMFAQQ1. What is your terms of packing?A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q2. What is your terms of payment?A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.Q3. What is your terms of delivery?A: EXW, FOB, CFR, CIF, DDU.Q4. How about your delivery time?A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.Q5. Can you produce according to the samples?A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.Q6. What is your sample policy?A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.Q7. Do you test all your goods before delivery?A: Yes, we have 100% test before deliveryQ8: How do you make our business long-term and good relationship?A:1. We keep good quality and competitive price to ensure our customers benefit ; 161 planetary gearmotor , high torque dc gear motor encoder, dc geared motor, 12v dc motor 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they comefrom.

Pulley Type

There are several types of pulleys. These include fixed pulleys, load multipliers and movable pulleys. Below is a description of each pulley type. A load multiplier is a special type of pulley with multiple wheels for increased lifting capacity. It is used in a wide range of applications including power transmission and construction. Some common uses of pulleys are listed below.

moving pulley

Movable pulleys work by transferring the weight of a load to another object of the same mass. Since a live pulley is inherently frictionless and weightless, the force required to lift a load with it is the same as the weight of the load. This principle applies to tall buildings and residences. It is an excellent choice for lifting heavy objects such as furniture and washing machines.

A pulley is a mechanical device with a wheel that rotates on a shaft. The axle is attached to the wheel and is usually fixed. The movable pulley can be fixed or movable, both of which can change the direction of the force on the rope. Some pulleys can also change the magnitude and direction of the force. They are ideal for a variety of applications, from lifting heavy objects to transporting objects.

Another type of movable pulley works by transmitting force to another object. It has a free axis and the total force provided by the rope tension is balanced. Since the tension on the rope is constant in each segment, pulling one end of the rope will double the force on the shaft, resulting in two mechanical advantages. This mechanical advantage is the main reason why movable pulleys are so versatile.

Another form of moving pulley is called a KWL diagram. The KWL diagram summarizes the basic concepts of the drive wheel. KWL diagrams are an excellent way to assess a student’s understanding of the concepts discussed in the course. Word questions are a great way to check whether students understand concepts. When students answer the word questions correctly, the answer is yes!

Fixed wheel pulley

If you need to move heavy objects, a single fixed wheel pulley is not a good choice. Using a single fixed pulley might be similar to using a handbag, but it’s not very convenient. This type of pulley system relies on friction to transmit motion. As a result, it can slip and isn’t always reliable. Fortunately, you can find other options that work just as well.

Fixed pulleys are the most basic type of pulley. They consist of grooved wheels and ropes attached to objects. These pulleys make lifting easier. Because the rope or cable only moves in one direction, the movement of the object feels lighter. And they are also easy to install. However, before you buy a fixed wheel pulley, make sure it is strong enough to support the weight of the load.

The disadvantages of fixed pulleys are obvious. One of them is the lack of mechanical advantage. A fixed pulley pulls up with the same force as a single moving pulley, and a single fixed pulley is not particularly effective as a force multiplier. However, the effect is more pronounced when you combine multiple fixed-wheel pulleys. You will get double the power! So what do fixed wheel pulleys have to offer?

Fixed wheel pulleys can be as small as a ring. A single ring pulley requires twice as much force as the weight being pulled. Adding more loops to the rope will reduce the effort required to pull the weight. The mechanical advantage of a fixed pulley is proportional to the number of strands running to the free pulley. A 100-pound pull on the free end will lift a 300-pound load.

composite pulley

Compound pulleys are pulleys that can be used to change the direction of a control wire. It can also be used to modify the mechanical force of the wire by moving the item it is connected to. In galleons, compound pulleys are more common. They are often combined with other ropes for mechanical advantage. Here are some common uses for composite pulleys.

The ideal mechanical advantage of a pulley is equal to the number of rope segments that pull up the load. This means that the more rope segments, the less force is required. A compound pulley will have the ideal mechanical advantage of 2, which means it will generate more force than a simple pulley. Composite pulleys are also more efficient at transmitting force because their number of rope segments is usually equal to the unit weight.

Composite pulley systems use more than two pulleys and ropes. More pulleys will reduce the force required to move heavier objects. They are usually used in large sailboats. The system is also used on construction sites. It can be used for a variety of applications, including lifting large objects or transmitting electricity. You can imagine how it would change your life if you had to move a large sailboat, but the result would be the same: a composite pulley system would make it easier to lift a large sailboat.

Composite pulleys are also known as fixed pulleys. The fixed pulley is stationary, and the movable pulley moves back and forth. The latter is more effective when used with a detachable cord or strap. On the other hand, a moving pulley is a moving pulley and it gives you a mechanical advantage. You can imagine this pulley on a flagpole.

load multiplier

The multiplication system has three basic parts: the rope grab, the connector, and the pulley. While some basic multipliers may combine the three parts, the concept remains the same. The multiplication system can make pulling the rope easier by reducing the amount of friction that occurs. Below are some examples of multiplication systems. A compact rope grab is a great option for resetting the multiplier.

The load reduction that a pulley system can achieve is proportional to the number of ropes used to support it. Although most utility pulley systems use only four ropes, the theoretical maximum load reduction is a quarter of the actual load. In other words, the four-wheel system only reduces the weight of a 1,000-pound load by a quarter. That would require 167 pounds of force, a far cry from the 500-pound load a single pulley system can achieve.

The mechanical advantage of a pulley system can be calculated by calculating the ratio between the forces exerted on each wire. For example, a 90-kilogram load is supported by three ropes, each weighing about thirty-five pounds. The ropes on pulleys A and B each carry a load of 60 kg. Using this formula, a single pulley system will yield a mechanical advantage over two tractors.

To calculate the force required to pull the rope over the pulley, measure the angle and deflection between the ropes. The deflection angle when added to the included angle should equal 180 degrees. A 75 degree angle requires 159% of the load force. This means a total load multiplier of four. This formula is an important tool for calculating the force multiple of the pulley.

Disadvantages of fixed pulleys

There are two basic types of pulleys: movable and fixed. Active pulleys are more advanced, allowing the pulley to move according to the load. They reduce the force required to lift the load. Active roller pulleys are more compact and therefore take up less space. Both types are good for lifting heavier objects, but they each have their pros and cons.

Fixed wheel pulleys can be used to lift heavy objects. This type of pulley consists of a wheel with a fixed shaft that has grooves on its edges for guiding ropes or cables. This is a simple machine as no motor or engine is required to lift objects. When two or more wheels are used together, the ropes around the wheels form a powerful hoist.

Single wheel pulleys are not suitable for lifting. They tend to push things down. Also, they are unreliable because they rely on friction and can slip. Also, a single wheel pulley would require a lot of space. Another disadvantage of fixed-wheel pulleys is that they make it difficult to move heavy objects easily. Single fixed-wheel pulleys also tend to slip easily, making them a poor choice for many applications.

Fixed wheel pulleys are also easier to install and maintain than manually operated ones. It requires less space and lubrication than manual pulleys. Manual pulleys can cause injury because the operator will be lifting the full weight of the heavy object. Additionally, rope slippage can lead to muscle strains and rope burns. And the system requires frequent maintenance.

China best Timing Belt Pulleys Sheave Industrial Tensioner Taper Bush Zero Backlash Aluminium Cast Iron Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley near me supplier

Product Description

Timing Belt Pulley Industrial Tensioner Taper Bush Lock Zero Backlash Aluminium Cast Iron Electric Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley

V-Belt Pulley:

If You Purchase An Alternator Just About Anywhere, It Will Not Include This Dual V-Belt Pulley Will Not Be Available & Your Must Transfer It From Your Old Alternator.However, If You Need This Pulley And Your Repair Shop Exchanged Your Alternator For A Core & Forgot To Swap It Out, This Is The Cure For Your Problem.This Dual Pulley Is Hard To Come By & Many Years Back & This One Is A Direct Fit For The Full Size Jeeps.This Dual V-Belt Pulley Has A Nice Chrome Finish & Is Made Of Higher Quality Materials For Strength & Durability.

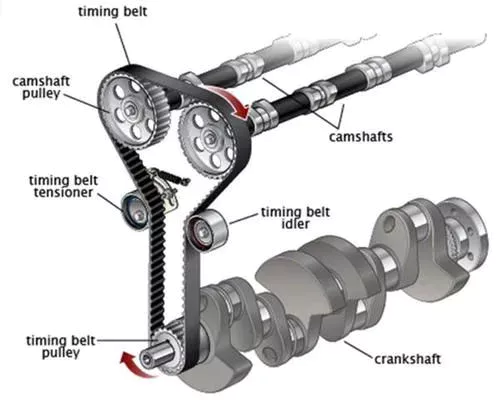

Timing pulley:

Related products:

Company:

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.