Product Description

Timing Pulley Toothed Synchronous Drives Pilot Bore Metric Pitch Sprocket Taper Bore 6 Inch V Belt Pulleys Wheels Sheave Suppliers Tensioner Automobile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

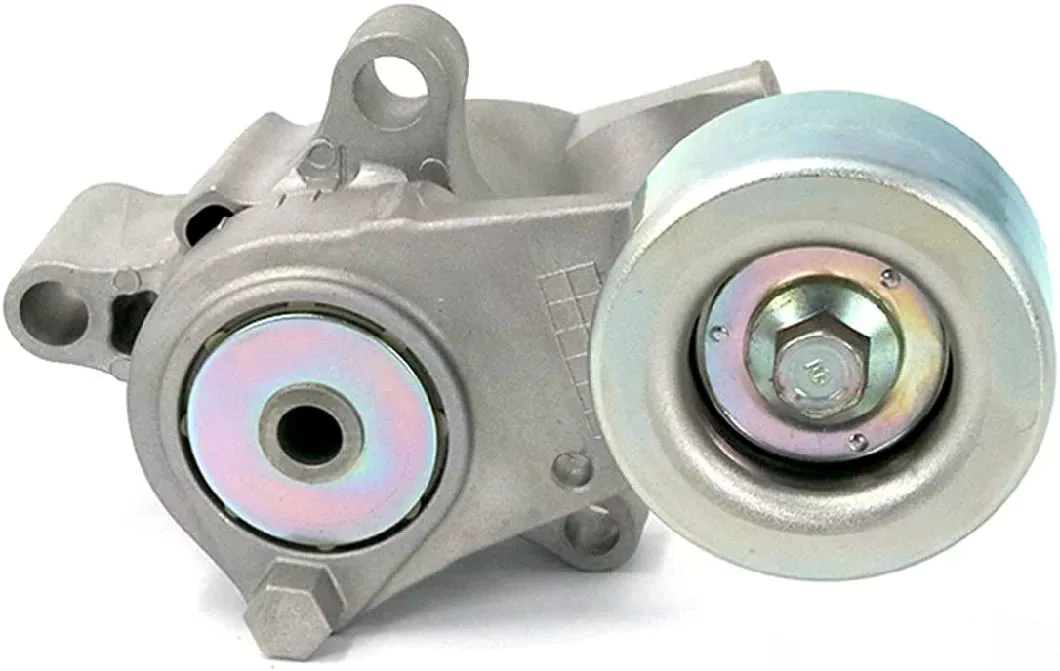

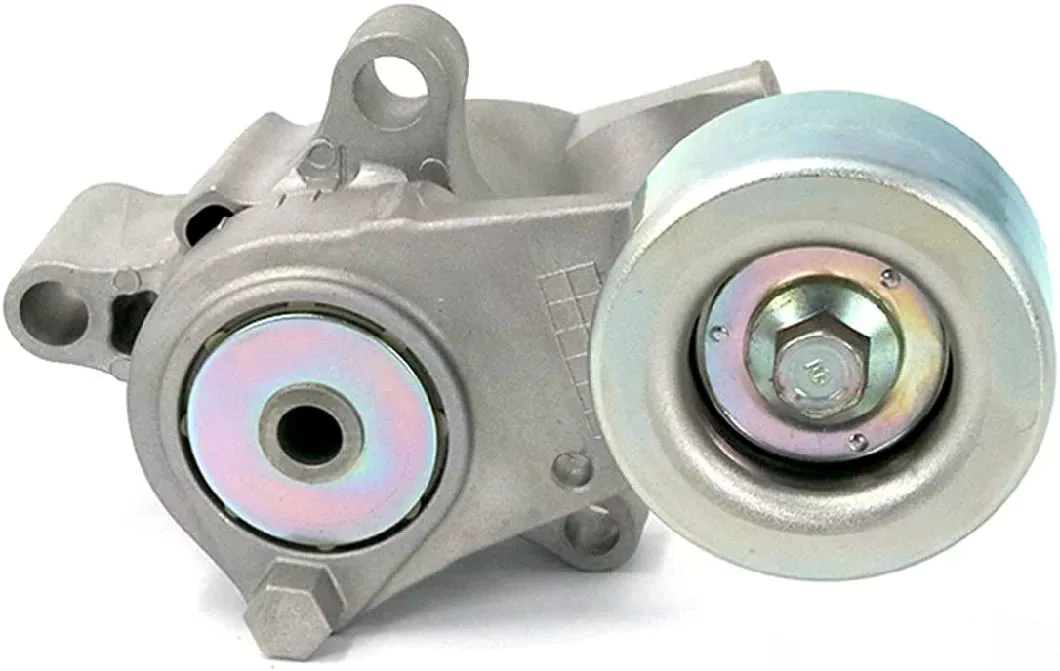

What are the reliability and durability aspects of drive belt tensioners in ensuring consistent tension?

Reliability and durability are crucial aspects of drive belt tensioners in ensuring consistent tension in a belt-driven system. Tensioners play a critical role in maintaining proper belt tension, which directly impacts the system’s performance, efficiency, and longevity. Here’s a detailed explanation of the reliability and durability aspects of drive belt tensioners:

- Component Quality and Materials:

- Load Capacity and Design:

- Resistance to Environmental Factors:

- Proper Lubrication and Maintenance:

- Quality Assurance and Testing:

The reliability and durability of a drive belt tensioner heavily depend on the quality of its components and materials. High-quality tensioners are manufactured using robust materials that can withstand the stresses and environmental conditions encountered in automotive and industrial applications. Components such as bearings, pulleys, springs, and mounting brackets should be designed and constructed to withstand continuous operation, resist wear, and maintain their performance over time. Tensioners built with durable materials and precise manufacturing processes are less prone to premature failure, ensuring consistent tension for a longer duration.

The load capacity and design of a drive belt tensioner are vital considerations for reliability and durability. Tensioners should be appropriately sized and engineered to handle the tension forces exerted by the belt and the driven system. If the tensioner is undersized or poorly designed, it may experience excessive stress, leading to accelerated wear, deformation, or failure. Manufacturers provide load capacity specifications for tensioners, indicating the maximum tension they can handle. By selecting a tensioner with sufficient load capacity and a robust design, consistent tension can be maintained reliably over the life of the belt-driven system.

Drive belt tensioners are exposed to various environmental factors that can impact their reliability and durability. Factors such as temperature extremes, humidity, dust, and chemical contaminants can affect the performance of tensioners and their components. Reliable tensioners are designed and constructed to resist these environmental factors. They may incorporate special coatings, seals, or materials that provide protection against corrosion, abrasion, or degradation. By withstanding environmental challenges, tensioners can maintain their functionality and ensure consistent tension even in demanding operating conditions.

Appropriate lubrication and regular maintenance are essential for ensuring the reliability and durability of drive belt tensioners. Bearings and moving parts within the tensioner require proper lubrication to reduce friction, prevent excessive wear, and maintain smooth operation. Manufacturers often provide guidelines on the recommended lubrication intervals and types of lubricants to use. Regular maintenance, including inspections, cleaning, and replacement of worn components, helps identify potential issues early and prevent catastrophic failures. By following proper lubrication and maintenance practices, the tensioner’s reliability and durability can be maximized, ensuring consistent tension throughout its lifespan.

Reliable manufacturers of drive belt tensioners employ stringent quality assurance processes and testing procedures to ensure the durability and consistency of their products. These processes may include material testing, dimensional checks, load capacity verification, and performance testing under various conditions. Through rigorous quality control measures, manufacturers can identify and rectify any potential manufacturing defects or design flaws that could compromise the tensioner’s reliability. By choosing tensioners from reputable manufacturers with robust quality assurance practices, the risk of premature failures and inconsistent tension can be significantly reduced.

In summary, the reliability and durability of drive belt tensioners play a crucial role in ensuring consistent tension in a belt-driven system. High-quality components and materials, appropriate load capacity and design, resistance to environmental factors, proper lubrication and maintenance practices, and reliable manufacturing processes contribute to the long-term performance and reliability of tensioners. By selecting and maintaining reliable tensioners, consistent tension can be maintained, leading to optimal system performance, reduced downtime, and extended belt life.

What is the impact of proper tensioning on the lifespan and reliability of drive belts in automotive and industrial settings?

Proper tensioning has a significant impact on the lifespan and reliability of drive belts in both automotive and industrial settings. Maintaining the correct tension in drive belts is crucial for their optimal performance and longevity. Here’s a detailed explanation of the impact of proper tensioning on drive belts:

- Lifespan:

- Reliability:

- Reduced Maintenance:

- Optimal Performance:

Proper tensioning significantly extends the lifespan of drive belts. When a belt is under-tensioned, it can slip, especially under heavy loads or during sudden acceleration, deceleration, or changes in direction. Belt slippage causes excessive friction, heat, and wear, leading to premature belt failure. On the other hand, over-tensioning can put excessive stress on the belt, leading to accelerated wear, stretching, and potential damage. By maintaining the proper tension, drive belt tensioners ensure that the belt operates within its optimal range, reducing wear and extending the belt’s lifespan.

Proper tensioning enhances the reliability of drive belts. When a belt is properly tensioned, it maintains consistent contact with the pulleys, ensuring efficient power transmission. This minimizes the risk of belt slippage, which can result in power loss, reduced performance, and potential damage to the driven components. In automotive settings, reliable belt operation is crucial for the proper functioning of engine accessories like the alternator, power steering pump, and air conditioning compressor. In industrial settings, reliable belt operation ensures uninterrupted power transmission and prevents costly downtime. By maintaining proper tension, drive belt tensioners play a vital role in ensuring the reliable operation of drive belts in automotive and industrial applications.

Proper tensioning can reduce the need for frequent belt adjustments and maintenance. When a belt is properly tensioned, it experiences minimal wear and stretching, reducing the frequency of tension adjustments. This saves time and effort in maintaining the belt system. In automotive settings, it means that the serpentine belt system can operate for longer intervals without requiring manual tension adjustments. In industrial settings, drive belts can operate more reliably and require fewer shutdowns for tensioning adjustments. By reducing maintenance requirements, proper tensioning contributes to improved efficiency and productivity in automotive and industrial applications.

Proper tensioning ensures optimal performance of drive belts. When a belt is correctly tensioned, it maintains proper engagement with the pulleys, allowing efficient power transfer. This optimizes the performance of driven components, such as alternators, pumps, and compressors. In automotive settings, proper belt tensioning helps ensure reliable operation of engine accessories, maintaining electrical charging, power steering, and air conditioning functions. In industrial settings, optimal belt tensioning ensures efficient power transmission, minimizing energy losses and maximizing the performance of machinery and equipment. By maintaining optimal performance, proper tensioning enhances the overall efficiency and functionality of drive belts in automotive and industrial applications.

In summary, proper tensioning has a significant impact on the lifespan and reliability of drive belts in automotive and industrial settings. It extends the belt’s lifespan, enhances reliability, reduces maintenance requirements, and ensures optimal performance. Drive belt tensioners play a crucial role in maintaining the proper tension of belts, contributing to the longevity and efficient operation of drive belts in various applications.

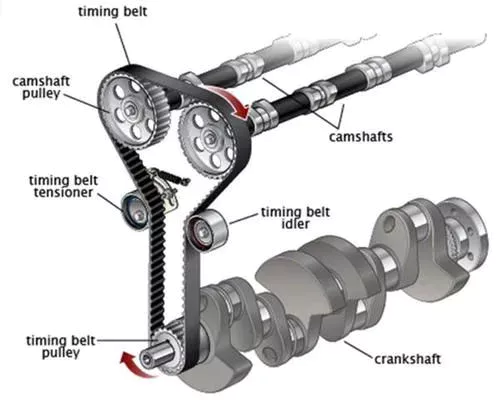

What is a drive belt tensioner, and how does it function in automotive and industrial applications?

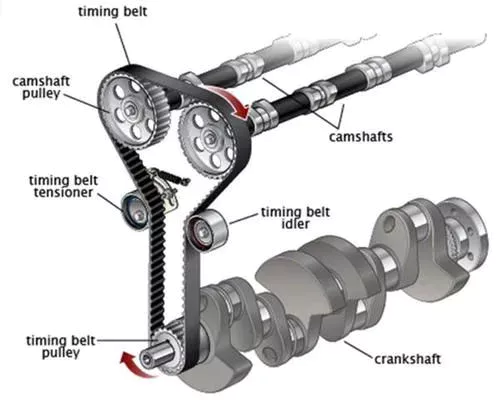

A drive belt tensioner is a mechanical component used in automotive and industrial applications to maintain proper tension in the drive belt system. It is designed to ensure that the belt remains tight and properly engaged with the pulleys, allowing for efficient power transmission. Here’s a detailed explanation of what a drive belt tensioner is and how it functions:

- Definition and Components:

- Function in Automotive Applications:

- Function in Industrial Applications:

- Functioning Mechanism:

- Benefits and Importance:

A drive belt tensioner, also known as a belt tensioner or a serpentine belt tensioner, is typically a spring-loaded or hydraulic mechanism that exerts constant tension on the drive belt. It consists of several components, including a tensioner pulley, an arm or bracket, a spring or hydraulic cylinder, and a pivot point. The tensioner pulley is responsible for applying tension to the belt, while the arm or bracket holds the pulley in place. The spring or hydraulic cylinder provides the force necessary to maintain tension, and the pivot point allows for movement and adjustment.

In automotive applications, drive belt tensioners are commonly used in the serpentine belt system. The serpentine belt is a single, long belt that drives various engine accessories, such as the alternator, power steering pump, air conditioning compressor, and water pump. The tensioner ensures that the serpentine belt remains properly tensioned, preventing slippage and ensuring efficient power transfer to these accessories. It compensates for belt stretch, wear, and load variations, maintaining consistent tension and optimizing the performance of the engine accessories.

In industrial applications, drive belt tensioners are employed in various belt drive systems. These systems may include multiple belts, such as V-belts or timing belts, driving different components in machinery or equipment. The tensioner’s role is to maintain proper tension in each belt, ensuring reliable power transmission and preventing slippage. It adapts to load variations, compensates for belt stretch and wear, and helps distribute the load evenly among the belts. By maintaining optimal tension, drive belt tensioners enhance the overall efficiency, reliability, and lifespan of the belt drive systems in industrial applications.

The functioning of a drive belt tensioner depends on its specific design, which can vary depending on the application and the type of tensioner used. In general, tensioners utilize the force generated by a spring or hydraulic cylinder to exert tension on the belt. The tensioner is typically mounted on an adjustable arm or bracket, allowing for movement and adjustment to maintain the desired tension. As the belt stretches or wears over time, the tensioner compensates by applying additional tension to keep the belt properly engaged with the pulleys. Some tensioners incorporate automatic self-adjustment mechanisms, while others may require manual adjustment or periodic inspection to ensure proper tension.

Drive belt tensioners offer several benefits and play a crucial role in automotive and industrial applications. They prevent slippage, optimize power transmission, and maintain consistent tension in the belt drive systems. By compensating for belt stretch, wear, and load variations, tensioners ensure reliable and efficient operation of the driven components. They reduce the risk of belt failure, minimize wear and fatigue, and extend the lifespan of the belts. Proper tensioning provided by drive belt tensioners enhances overall system performance, reduces maintenance requirements, and increases the reliability and longevity of the belt drive systems.

In summary, a drive belt tensioner is a mechanical component that maintains proper tension in the drive belt system. It functions by applying tension to the belt using a pulley, spring, or hydraulic cylinder. In automotive applications, tensioners optimize power transmission in the serpentine belt system, while in industrial applications, they ensure reliable power transfer in various belt drive systems. By compensating for belt stretch, wear, and load variations, drive belt tensioners enhance efficiency, reduce wear, and extend the lifespan of the belts, contributing to the overall performance and reliability of automotive and industrial machinery.

editor by CX 2024-04-10

China Hot selling Accessory Drive EPDM CZPT V Ribbed Belt Tensioner Belt 6pk1555 06D903137f for Audi A6 C6 4f 2.0t near me supplier

Product Description

-

About 6,250 results (0.37 seconds)

06D95717F – Spareto 06d95717f

06D95717F – V-ribbed belt, v-ribbed belt set OE number by AUDI, SEAT, SKODA, VAG, VW · Replacement parts compatible with OE numbers · CONTITECH 6PK1555 · €11.80.

06D95717F from spareto.

Images for 06D95717Fdrive belt

dây curoa

903 137

ribbed belt

06d 903gates

audi a6

timing beltjeneratör yedekdayco

remen

v ribbed

avant quattros6 avant

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

Image result for 06D95717F

View all

Feedback

View allV-Ribbed belt, V-Ribbed belt set OE – NUMBER 06D95717Fhttps://www.autodoc.co.uk › Car parts › Poly v-belt

V-Ribbed belt, V-Ribbed belt set OE – NUMBER 06D95717F … An OEM number is a unique code containing letters and digits. Car manufacturers use them to mark every …NEW AUDI A6 C6 POLY V BELT 06D95717F ORIGINAL | eBayhttps://www.ebay. itm

NEW AUDI A6 C6 POLY V BELT 06D95717F ORIGINAL. NEW AUDI A6 C6 POLY V BELT 06D95717F ORIGINAL. Item Information. Condition: NewNew. Price: US $35.30.OE Number 06D95717F: V-ribbed belt – Online car partshttps://www.onlinecarparts.co.uk › oenumber › 06d903…

24/7 online OEM 06D95717F – V-ribbed belt Original OEM quality! Search parts for your vehicle by OEM number and buy online.V-ribbed belt 06D95717F – OE Number – Car Partshttps://www.123spareparts.co.uk › oem-number › 06d9…

Supplementary Info: Micro-V ; Length [mm]: 1555; Number of ribs: 6; Material: Polyester, EPDM (ethylene propylene diene Monomer (M-class) rubber) …V-Ribbed Belts: VAG (VW, AUDI, SKODA) 06D95717F Belt and Chain Drive › V-belt

Buy V-Ribbed Belts: VAG (VW, AUDI, SKODA) 06D95717F online at boodmo. Best prices in India. Order now!POLY-V BELT 6 CZPT – Febest #88128-6L1555 POLYV_BELT_6_RIBS

POLY-V BELT 6 CZPT W 1 YEAR WARRANTY – COMPATIBLE WITH Chevrolet aveo/sonic europe 2012-2017 [eu], Chevrolet cruze hatchback – europe 2012-2017 [eu], …VAG 06D95717F – FitinParthttps://www.fitinpart.sg › product

Part Number 06D95717F ; Offers · We deliver to United States, check rate options and transit times in the shopping cart. ; MDAG. 10. 12d. US$65.30 ; MSAG. 10. 22d.Dây Curroa Tng Audi A6 VW 06D95717F – Ph tùng ô …https://phutungotonamchau da…· Translate this page

Dây Curroa Tng Audi A6 VW 06D95717F. GIÁ: LIÊN H. Danh mc: Bentley – Volkswagen – Audi T khóa: 06D95717F, Dây Curroa Tng Audi, Dây Curroa Tng Audi …

Types of V-Belts and Their Properties

A v-belt’s inside length and pitch are determined by measuring along the bottom side. The included angle of a v-belt is measured from its flanks when it is extended. Most v-belt sections are 40 degrees. There are different types of v-belts, and the dimensions of each are standardized by different organizations. This article will introduce the different types of v-belts and their properties.

Notched v-belts reduce bending stress

Notched V-belts reduce bending stress by reducing the axial length of the belt by 2 or more notches. These notches are characterized by different profiles, which differ in the pitch angle and the inside length. ISO and DIN standards are followed by the manufacturers of these belts. Notched v-belts are used on industrial machinery in countries other than the US.

Compared to the standard V-belts, notched ones are designed to resist bending stress better and offer better heat dissipation. They also last longer and run cooler than standard V-belts. Furthermore, they are about 2 percent more energy efficient than their standard counterparts. Therefore, notched V-belts are a viable replacement for standard V-belts.

Notched V-belts are commonly used in industrial applications because of their low price, ease of installation, and availability of many sizes. Another advantage of notched V-belts is that they provide more wedging force and higher load capacity. Notched V-belts have a wider v-groove than flat ones, which makes them more effective for heavy-duty applications.

Notched V-belts also provide better traction. They reduce bending stress, which is beneficial for preventing fatigue and tearing of v-belts. Additionally, v-belts can be installed in an existing equipment to add more performance. And with proper maintenance and installation, notched V-belts will provide trouble-free service for many years to come.

Ribbed v-belts reduce heat dissipation

Various kinds of v-belts are available for varying applications. The more popular types are the fractional horsepower and the double-V. Fractional horsepower v-belts are designed for light-duty applications, such as machine shop equipment and household appliances. The common sectional names are 2L, 3L, 4L, and 5L. The L in each of these belts refers to the top width of the belt, multiplied by 1 eighth inch.

Unlike conventional belts, ribbed v-belts are flexible, making them ideal for use in vibrating loads. They reduce heat dissipation and can be ordered in single or multiple sets to match your application. However, ribbed v-belts should not be mounted on deep-groove sheaves, as this can cause the belt to turn over. If you use deep-groove sheaves, the risk of rupture is very high. Deep-groove sheaves can also cut banded belts. Extremely worn sheaves can also cause the belt to rip.

The 2 types of ribbed v-belts differ in their construction and application. While both types have trapezium cross-sections, they are similar in that they are made of polyurethane or other durable materials. Ribbed v-belts have an additional layer of fabric on the elastomer core for reduced noise and better heat dissipation.

Ribbed v-belts are available in a variety of sizes, including trough v-belts. Their cross-sections are categorized by their top and bottom widths and depths. The included angle of most v-belt sections is approximately 40 degrees. Different types of v-belts have different cross-sections, and these cross-sections are standardized by various organizations.

As the load increases, a ribbed v-belt will wedge into the groove and decrease the amount of friction needed to maintain the correct torque. Flat belts can track off the pulleys due to friction. However, V-belts are more stable and require less width than flat belts. The main advantage of ribbed v-belts is their increased efficiency.

The global-local finite-element model is also used to calculate the maximum and minimum J-integrals during a belt’s running cycle. The data is then used to evaluate the durability of ribbed v-belts in various applications. The numerical models used for the calculations involve a ribbed V-belt with 5 full ribs.

Cogged v-belts increase lateral rigidity to reduce belt whip

Cogged v-belts are designed for maximum performance and durability on even the harshest drive systems. These belts are made from high-modulus polyester cords that resist hardening and stretch and provide superior balance and strength. They also feature raw-edge sidewalls to reduce slip and drive vibration. In addition, they have specially-formulated rubber compounds for oil resistance. CZPT Cog-Belt offers substantial savings in downtime, energy consumption and horsepower.

A double cogged v-belt combines the benefits of cogged and double vee-belts. Its bonded reinforced tie band offers enhanced flexibility and reduces belt whipping in multiple-belt drives. Double cogged v-belt dimensions vary depending on the standards of the manufacturer. Regardless of the type, you’ll want to use a belt that is aligned correctly.

Standard v-belts are also known as wrapped or raw edge v-belts. Wrapped V-belts feature fabric covers above and beneath the cord to increase lateral rigidity and reduce belt whip. Cogged V-belts also have fabric covers to prevent wear on the core and increase the belt’s operating temperature. They’re ideally suited for applications that require high-temperature operation.

Cogged V-belts can significantly decrease energy consumption and improve power transmission capabilities. They also have a bias-cut cover stock that provides axial and lateral stability while preserving the cord integrity. A fiber loaded cogged construction offers optimum flexibility while minimizing heat buildup. It can be installed on any type of drive, including chain conveyors and industrial-grade machines.

The two-layer tie-band permanently bonds multiple belts together. This provides maximum cord support, heavy shock absorption, and stability. The belts are also engineered with patented banding processes that eliminate belt turnover and distribute load evenly across the drive. CZPT Cog-Band Belts minimize belt whip and provide stability. They also minimize belt turnover and rollover in heavy-duty industrial applications.

A classic v-belt is the most common and economical belt. Its nominal dimensions are 1/2″ to 1-11/2″ wide and 16″ to 400 inches long. The width is usually 40 degrees. Different organizations use different cross-sections to classify v-belts. The following table provides a general comparison of the 2 types. The Cogged V-Belt is designed to reduce belt whip by increasing the lateral rigidity of the belt.

Cogged v-belts provide superior environmental resistance

The patented design of the Dayco V-Belt provides maximum power transmission while combining the benefits of a cogged belt and raw-edge construction. The belt’s top cogged design helps increase air flow around it, preventing deterioration and extending its useful life. The belt’s three-ply design features neoprene impregnated fabric for superior durability and a specially-formulated polyester cord for increased strength and stability.

A variety of v-belts are available, with cogged and notched versions presenting unique characteristics. Cogged V-belts are more flexible than uncogged versions and feature ‘X’-shaped grooves for enhanced heat dissipation. Cogged V-belts are interchangeable with conventional v-belts, although their ‘X’ design is most common. Hexagonal v-belts are a popular option for applications where traction is needed.

Another type of Cogged V-belt is designed specifically for outdoor power equipment. This v-belt is brown, with smooth clutching covers. Its aramid cord is very strong and provides superior durability in adverse conditions. Cogged V-belts can withstand severe shock loads and are therefore ideal for outdoor power equipment. Furthermore, they offer superior environmental resistance, minimal stretch, and a long service life.

A Cogged V-belt is composed of tensile cords that are supported by a rubber stock. Different manufacturers use different synthetic rubber stocks for this purpose. These materials help to extend the belt’s operating temperature range and resist premature failure. In addition to tensile cords, the belt’s body is covered with a fabric cover. The fabric is treated to form a chemical bond with the core materials, which allows it to withstand constant bending.

China high quality Rubber V Belt Tensioner Engine Rubber Fan Drive V Belt Supplier with Best Sales

Product Description

Product Description:

The top and the bottom are encased by the weapper, Both sides are rubber . V belt of tooth shape groove is designed for the bottom to improve the tlexral property.

| No. | Name | Function | Material |

| 1 | Top Fabric | Protect the CZPT tensile member | Polyester Cotton Canvas |

| 2 | Core Cord | Nuclear material to pass the dynamicTop Fabric force | Polyester |

| 3 | Bottom Rubber | Side compression resistant and section | CR,EPDM |

| 4 | Bottom Fabric | Absorb the impact and prevent crack of the core rubber | Elastic Fabric |

| Section Size of lndustrial Raw Edge V Belts |

| Type | Top width (mm) | Belt Thickness (mm) | Angle(°) |

| HM | 10.5 | 8.0 | 38 |

| AX | 13 | 8.0 | 38 |

| BX | 17 | 11 | 38 |

| CX | 22 | 14 | 38 |

| DX | 32 | 19 | 38 |

| EX | 38 | 23 | 38 |

| Section Size of Raw Edge Narrow Belts |

| Type | Top width | Belt Thickness | Angle |

| XPZ | 9.7 | 8.0 | 40 |

| XPA | 12.7 | 10 | 40 |

| XPB | 16.3 | 13 | 40 |

| XPC | 22 | 18 | 40 |

| 9NX | 9.5 | 8 | 40 |

| 15NX | 16 | 13.5 | 40 |

| 25NX | 25.4 | 23 | 40 |

| Section Size of Raw Edge V Belts for Automobile |

| Type | Top width | Wrapped V belt | Raw edge V belt | REF | REC | Angle |

| AV-10/9.5 | 10.0 | 8.0 | 7.5 | 7.5 | 8.0 | 40 |

| AV-13/12.5 | 13.0 | 10.0 | 8.5 | 8.5 | 9.0 | 40 |

| AV-15 | 15.0 | 9.0 | – | – | – | 40 |

| AV-17 | 16.5 | 10.5 | 9.5 | 9.5 | 11.0 | 40 |

| AV-22 | 22.0 | 14.0 | – | – | 13.0 | 40 |

Company introduction:

The First:HangZhou Grand AUTO PARTS CO.,LTD.is a professional auto parts corporation with operations including development,productnumber of high-tech production bases in mainland China.

The Second:We have established partnerships with big purchasers and the renowned brands in France and Egypt and Iraq to carry out the OEM.

The Third:The products are sold into over 50 countries around the world with Europe, America,the middle east and the southeastAsia and Africa as the main destinations.

What Is a V-Belt?

What is a v-belt? It is a rubber belt that is trapezium-shaped and has an elastomer core that holds the parts together. Its elastomer core is generally made of polyurethane and has good shock resistance and flexural strength. V-belts sometimes have 2 sections, 1 of which is a compression rubber and the other cushion rubber. They can be narrow or wide, depending on their use.

Classical V-belts replace leather belts

Classical V-belts are a popular choice among truck drivers because they are more durable. They are typically made of polymer or rubber, with fibers from other materials added for reinforcement. These belts are a good replacement for leather belts and offer many benefits. They are durable, offer excellent temperature and oil resistance, and are easy to use. If you’re considering replacing your current belt, consider buying a replacement belt made of the same material.

Most classical V-belts are used individually and come in A and B sizes. They are rarely used in single-belt drives. Buying several A or B belts instead of 1 C belt can save money. The narrow V-belts also provide higher power ratings. This is due to their narrow profile, which places more of the reinforcing cord under the sheave. Narrow V-belts are ideal for heavy duty applications.

When you’re replacing an existing V-belt, you’ll need to measure its top width and circumference. Once you’ve determined these parameters, you’ll be able to select the right replacement belt. Make sure to take measurements of the belt’s dimensions and top width before ordering. Using these measurements will help you determine the best size for your new belt. You’ll be able to tell whether you need a larger or smaller belt after measuring the top width and circumference.

If you’re looking to replace your leather belt with a belt made of synthetic material, a Classical V-belt may be the right choice. Classical V-belts are available in many materials and are more durable than leather. And because they are so versatile, they are the perfect replacement for your current belts. You’ll be glad you did. So, don’t be afraid to experiment with this type of belt. They’ll work well in any setting, including heavy equipment.

When buying a Classical V-belt, be sure to check the dimensions and type of belt you choose. These are available in notched or cogged designs. Notches are a great way to reduce bending stress. Notches also help dissipate heat from the belt, a major factor in premature belt failure. Notched V-belts are designed to balance a combination of flexibility and tensile cord support. They are spaced properly to minimize cracking and undercord damage.

Unlike leather belts, Classical V-belts are made of synthetic materials. They are easy to install, have a wide range of sizes, and come in light to heavy-duty varieties. The V-belt’s trapezoidal shape helps it track in the grooves of pulleys and prevents it from slipping while in use. It also helps in reducing power loss, since it’s easier to grip the pulleys than leather.

Narrow v-belts are more efficient

There are 5 basic types of V-belts. Their differences in cross-sectional size and power transmission make them superior to multiple single v-belts. The diagram below shows these types and how each differs from 1 another. The included angle of each belt is 40 degrees. The lower number indicates the more efficient version. Narrow V-belts are generally less expensive. Narrow v-belts are generally more efficient than wider belts.

There are several factors that influence a V-belt’s efficiency. Although the efficiency is high when a new belt is installed, the efficiency can drop to the low nineties. However, these belts are relatively resilient, and even with lower efficiency can function properly. Even if the efficiency of a V-belt is lower than it could be, it will still function. In fact, the higher the efficiency, the more energy it will save.

The first is the type of pulley. A narrow V-belt is more flexible than its wider counterpart. The belt pitch diameter is 32deg or 38deg. In addition, the belt can be cogged for added flexibility. In this way, the belt will not touch the bottom of the groove, but will only contact the inclined flanks. Without this wedge effect, the belt’s total friction force is higher. This means that it can transfer higher forces.

While a V-belt looks like a glorified rubber band, it has undergone tremendous technological development since it was first used in 1917. Synthetic rubber compounds and other cover materials have replaced rubber in the belt. New construction methods, tensile cord improvements, and cross-section profiles have resulted in a confusing variety of V-belts. Their differences, however, are based on the type of application for which they’re used.

Another type of V-belt is the raw edge variety. This type of belt is commonly used in manufacturing facilities. This type of belt requires less energy to operate. The raw edge also resists hardening. This is important since unmatched flexibility results in a smooth belt. Also, notched V-belts reduce vibration by 80%. Further, angular misalignment increases the risk of premature failure of a V-belt.

These belts differ in their overall design. While conventional V-belts are more common, narrow V-belts are more efficient and versatile. They are made of different types of rubber and reinforcements, which combine to create a trapezium-shaped cross-section. They can handle fractional loads and even 500 horsepower. Furthermore, their durability is largely dependent on their ability to withstand poor operating conditions.

Double-sided v-belts have unique features. These belts are used in applications with multiple pulleys. They can be operated clockwise or counter-clockwise. They can also be used to drive around multiple reverse bends. Further, they are more efficient and quieter than their counterparts. Finally, double-sided v-belts have 2 compression cores. The tension cord runs through both sections.

Double cogged v-belts increase lateral rigidity to reduce belt whip

A double cogged v-belt is a hybrid of a traditional double versus a cogged vee-belt. These belts are useful for applications that require a large amount of flexibility without compromising durability. The double cogged design also allows the belt to follow a serpentine path. The varying dimensions of a double cogged v-belt depend on manufacturer standards.

A v-belt is measured by defining the centerline, the inside length of the v-belt, and the pitch line, which is the distance between the top and bottom sides of the trapezium. The width and height of a v-belt are defined by its cross-section. Each cross-section is given a different designation, including the width and height.

A standard V-belt is a v-belt with a fabric cover. It provides firmness in a smaller space and is less prone to belt whip when used in heavy-duty applications. Its slim profile and light gauge tensile cord make it suitable for many industrial applications. The standard length of a double cogged v-belt varies from 530 to 3,000 mm.

Single cogged v-belts are commonly used in manufacturing machines that operate in close proximity to 1 another. Single cogged v-belts increase lateral rigidity and reduce belt whip. They are also ideal for heavy-duty applications, such as in mining or quarrying. Double cogged v-belts also increase lateral rigidity to minimize belt whip.

The elastomer core of a v-belt is surrounded by tension cords. These tension cords are embedded into the rubber compound, creating a composite structure that provides a high degree of shock resistance and flexural strength. The tension cords are often made of steel, polyester, or aramid fibers. This material makes it much stronger and more durable.

A double cogged v-belt is a highly rigid option for applications where lateral rigidity is an important concern. The double cogged design also increases lateral rigidity to reduce belt whip and enhances power transmission efficiency. Double cogged v-belts also offer positive slip-proof engagement. These belts are also easier to maintain, require less maintenance, and require no lubrication.

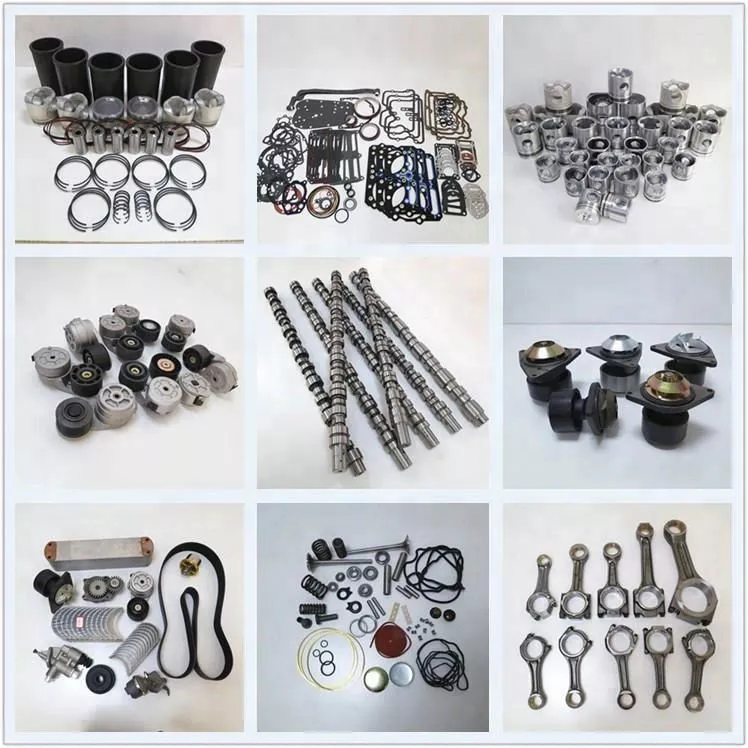

China best Timing Belt Pulleys Sheave Industrial Tensioner Taper Bush Zero Backlash Aluminium Cast Iron Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley near me supplier

Product Description

Timing Belt Pulley Industrial Tensioner Taper Bush Lock Zero Backlash Aluminium Cast Iron Electric Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley

V-Belt Pulley:

If You Purchase An Alternator Just About Anywhere, It Will Not Include This Dual V-Belt Pulley Will Not Be Available & Your Must Transfer It From Your Old Alternator.However, If You Need This Pulley And Your Repair Shop Exchanged Your Alternator For A Core & Forgot To Swap It Out, This Is The Cure For Your Problem.This Dual Pulley Is Hard To Come By & Many Years Back & This One Is A Direct Fit For The Full Size Jeeps.This Dual V-Belt Pulley Has A Nice Chrome Finish & Is Made Of Higher Quality Materials For Strength & Durability.

Timing pulley:

Related products:

Company:

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.

China high quality High Quality Auto Spare Parts Belt Drive Timing Belt CZPT Pulley Tensioner Pulley OEM 201129 6577227 6710259 CZPT ESCORT V Convertible (ALL) 1.6 16V XR3i with high quality

Product Description

Product Description

China Manufacturer Auto Parts Timing Belt Xihu (West Lake) Dis. Pulley Tensioner Pulley OEM 8A1 for Peugeot 308 Series

Water Pump for CITROEN

Water Pump for PEUGEOT

All kinds of car water pumps can be produced for you. Welcome to your inquiry.

| MIC NO. | REF&OEM NO | APPLICATION | YEAR | PHOTO |

| TB33FD9201 | 201129 928.F6A.228-AB 6577227 6715719 928F6A228AB |

FORD ESCORT CLASSIC (AAL, ABL) 1.6 16V FORD ESCORT CLASSIC Turnier (ANL) 1.6 16V FORD ESCORT V (AAL, ABL) 1.6 i 16V FORD ESCORT V (AAL, ABL) 1.8 16V XR3i FORD ESCORT V (AAL, ABL) 1.8 XR3i 16V 4×4 FORD ESCORT V Convertible (ALL) 1.6 16V XR3i FORD ESCORT V Convertible (ALL) 1.6 i 16V FORD ESCORT V Convertible (ALL) 1.8 16V XR3i FORD ESCORT V Saloon (AFL) 1.6 i 16V FORD ESCORT V Turnier (ANL) 1.6 i 16V FORD ESCORT V Turnier (ANL) 1.8 16V FORD ESCORT V Turnier (ANL) 1.8 i 16V FORD ESCORT VI (GAL, AAL, ABL) 1.6 16V FORD ESCORT VI (GAL, AAL, ABL) 1.6 16V 4×4 FORD ESCORT VI (GAL, AAL, ABL) 1.6 i 16V FORD ESCORT VI (GAL, AAL, ABL) 1.8 16V FORD ESCORT VI Convertible (ALL) 1.8 16V XR3i FORD ESCORT VI Saloon (GAL, AFL) 1.6 i 16V FORD ESCORT VI Saloon (GAL, AFL) 1.8 16V FORD ESCORT VI Turnier (GAL, ANL) 1.6 16V FORD ESCORT VI Turnier (GAL, ANL) 1.6 i 16V FORD ESCORT VI Turnier (GAL, ANL) 1.8 16V |

1998-2000 1999-2000 1992-1995 1992-1995 1993-1995 1992-1995 1994-1995 1992-1995 1993-1995 1992-1995 1992-1995 1993-1995 1995-1998 1995-1998 1995-1995 1995-1998 1995-2000 1995-1999 1995-1999 1995-1999 1995-1995 1995-1999 |

Company Profile

Our Factory

Exhibition Shows

FAQ

Q1: Are you a trading company or manufacturer?

A1: We are industrial and export combination.

Q2: If there’s any quality problem, what would you do to guarantee our rights?

Q2: We seldom get complains from our customers so far. If it really happens, we’ll be responsible for that.

Q3: How long is your delivery time?

Q3: Around 30-45 days if no stock; Around 7 days when stock available.

Q4: What’s your sample policy?

A4: Samples under $50.0 will be no charge, however the freight charge should be borne on buyer’s account.

Normal delivery time will be 4 days when stock available.

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China factory Fan Belt Tensioner Pulley V Ribbed Belt Idler for Combo 94 to 01 wholesaler

Product Description

Fan Belt Tensioner Pulley V Ribbed Belt Idler For Combo 94 to 01

Item specifics:

|

Brand: |

YB |

Manufacturer Part NO.: |

0166D7011 |

|

Delivery Time: |

30 Days |

Warranty: |

1 Year or 50000 KM |

|

Port Of Shipment |

HangZhou Or ZheJiang Port, China |

Package: |

Neutral box, Customized box |

|

Car Model: |

Opel |

Reference OEM: |

90409238 651463 134571 134571 T36038 532571910 VKM35002 93297272 |

Application:

|

Model |

Engine |

Displacement |

Power |

Hp |

Type |

Year |

|

OPELCORSA B (73_, 78_, 79_) |

(1993/03 – 2002/12)

|

|||||

|

OPELSENATOR B (29_) |

(1987/09 – 1993/09)

|

|||||

|

OPELOMEGA A Estate (66_, 67_) |

(1986/09 – 1994/05)

|

|||||

|

OPELOMEGA A (16_, 17_, 19_) |

(1986/09 – 1994/05)

|

|||||

|

OPELASTRA F (56_, 57_) |

(1991/09 – 1998/09)

|

|||||

|

OPELASTRA F Convertible (53_B) |

(1993/03 – 2001/03)

|

|||||

|

OPELASTRA F Hatchback (53_, 54_, 58_, 59_) |

(1991/09 – 1998/01)

|

|||||

|

OPELASTRA F Estate (51_, 52_) |

(1991/09 – 1998/01)

|

|||||

|

OPELTIGRA (95_) |

(1994/07 – 2000/12)

|

|||||

|

OPELCORSA B Box (73_) |

(1999/08 – 2000/09)

|

|||||

|

VAUXHALLASTRA Mk III (F) Hatchback |

(1991/09 – 1998/02)

|

|||||

|

VAUXHALLASTRA Mk III (F) Estate |

(1991/03 – 1998/02)

|

|||||

|

VAUXHALLCORSA Mk I (B) |

(1992/12 – 2000/09)

|

|||||

|

VAUXHALLSENATOR Mk II (B) |

(1987/09 – 1993/09)

|

|||||

|

VAUXHALLTIGRA Mk I (F07) |

(1994/07 – 2000/12)

|

|||||

|

VAUXHALLASTRA Mk III (F) |

(1991/09 – 1998/09)

|

|||||

|

VAUXHALLASTRA Mk III (F) Convertible |

(1993/03 – 2001/03)

|

|||||

|

VAUXHALLCORSAVAN Mk I (B) |

(1994/01 – 2000/09)

|

Company Details:

HangZhou CZPT Auto Parts Industry Co., Ltd is a family owned company, established in 2005.

As a real, direct and professional manufacture in China, CZPT has grown to become 1 of greatest manfacturer and exporter in Performance parts, include intake system, exhaust system, cooling system, interior&exterior parts etc.

We own a factory located in HangZhou, HangZhou, which has 8000 square meter, tens of machine, 150 workers, 15 person sales tean, 5 R&D department. Our customers cover North American, South American, Asia, Middle east and Europe. We export the millions of USD per year. Looking forward to have a nice cooperation with you

Why Choose YiBai?

It’s simple. The YiBai Company is built on delivering more Quality, Reliability, and Value than any other manufacturer. Whether supplying the world’s automakers with reliable OE parts, or developing aftermarket replacement parts at or above spec, YiBai’s line of products are built to deliver superior all-around performance every day.

Aftermarket Parts Built At or Above Specification

The quality of YiBai parts is guaranteed because every component that leaves a YiBai factory has been designed with precision, manufactured to the strictest OE standards or above, and subjected to rigorous safety and performance tests. In the end, it all comes down to quality – that’s what the YiBai name stands for.

Measure Everything for a First Time Fit

Our First Time Fit philosophy attracts attention throughout the automotive world, while our commitment to pushing technology into the future and continually sets us apart around the globe.First Time Fit is a promise that YiBai makes to the aftermarket, by providing products that are OE grade or better – and fits the first time.

Our Service

1. OEM Manufacturing welcome: Product, Package…

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every 2 days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of delivery?

A: EXW, FOB CIF, DDU.

Q3. How about your delivery time?

A: Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China Hot selling V Ribbed Belt Tensioner Lever for CZPT OE 166200L020 1662030031 1662030030 56980 CZPT Pulley with Best Sales

Product Description

Detailed Photos

V Ribbed Belt Tensioner Lever for CZPT OE 1662.2

VKBA523

482A/472

VKBA 5038

35BWD16

VKM14103

Company Profile

ZheJiang Mighty Machinery Co. Ltd is a professional manufacturer of auto bearings for more than 20 years. We provide a one-stop service for our customers. Our main products include wheel bearings & hub assembly, belt tensioners, clutch release bearings, and other parts.

Relying on the professional and rich manufacturing experience and many substantial factories which stable cooperated for many years, Mighty suppliers customers high-quality products at very competitive prices.

Customer’s satisfaction is our First Priority, We adhere to the concept of ” Quality First, Customer First”. We will continue to provide high-quality products and the best services to our customers and build up CZPT long-time friendship partners.

Our Advantages

More than 20 years of manufacturing and exporting experience

OEM manufacturing available

Full range, large stock

Quickly feedback

One year warranty

One-stop service

On-time delivery

Packaging & Shipping

FAQ

1. What’s the minimum order quantity?

We don’t have the minimum order quantity. We can also provide free samples, but you need to pay the freight.

2. Do you provide ODM&OEM order service?

Yes, we provide ODM&OEM services to customers around the world, and we can customize different brands and different sizes of pacakging boxes according to customers’ requirements.

3. After-sales service and warranty time

We guarantee that our products will be free from defects in materials and workmanship within 12 months from the date of delivery. The warranty is void due to improper use, incorrect installation, and physical damage.

4. How to place an order?

Send us an email of the models, brand, quantity, consignee information, model of transportation, and payment

Confirm payment and arrange the production.

5. What are your packing conditions?

We use standardized export packaging and environmental protection packaging materials. If you have a legally registered patent, we will package the goods in your brand box after receiving your authorization

6. What are your payment terms?

T/T is 30% of the payment in advance and 70% balance before delivery. Before you pay the balance, we will show you photos or videos of the products and packaging.

7. How long is your delivery time?

The delivery time of sample order is 3-5 days, and that of a batch order is 5-45 days. The exact delivery time depends on the item and the quantity you ordered.

8. Do you test all products before delivery?

Yes, according to ISO standards, we have professional Q/C personnel, precision testing instruments, and an internal inspection system. We control the quality of every process from material receiving to packaging to ensure that you receive high-quality products

The Advantages and Disadvantages of Neoprene Timing Belts

The timing belt is an important component of an automobile engine. Made of special materials, this belt coordinates the rotational motion of the crankshaft with the camshaft. The coordinated precision is essential for sustainable combustion, and ensures that the valves in the combustion chamber open at the right times. Timing belts determine the engine’s pace, so it is essential that they perform at high synchronicity and strong enough to operate in extreme conditions.

Fabric timing belt

A timing belt is made of a yarn that has been crimped and woven into a mating surface, called the engagement surface. This yarn, known as the warp, must be able to stretch from a substantially flat state along irregularities in the mold. It must be flexible enough to stretch by several tens of percent under low load conditions. The warp yarn of a timing belt is made of synthetic fiber and is crimped into the right shape to be stretched easily.

This fabric can be used without thickening the base cloth. It can contain a large number of warp threads, and its wear resistance can be enhanced over time. The timing belt of the present invention does not crack or wear out after a long time of use. The base cloth does not wear out, which allows the timing belt to last for a long time. This makes it an extremely durable material. To learn more, read on.

The teeth of a timing belt are made of tough rubber and a nylon fabric facing. The fabric is coated with a plastic compound that gives it its shape and covers the cord. The materials used to make these belts vary, but all are strong and durable. They are also suitable for high-load applications. In addition to nylon timing belts, strongbelt premiums are also available. In addition to nylon and neoprene timing belts, they are also compatible with RPP and HTD pulleys.

The teeth of timing belts are made of high-strength polychloroprene elastomer. The teeth are made of a special manufacturing process that ensures good adhesion. The facing fabric is made of low-elongation glass cord and is covered by a polyamide fabric that has a low coefficient of friction. If you need an exact fit, you can buy a high-quality belt from TransDev.

Neoprene timing belt

When it comes to dependable drive belts, neoprene is hard to beat. It’s widely used in insulated clothing and weather stripping, and has been a key component in the development of timing belts since the late 1970s. And because it’s so hardy, neoprene timing belts are incredibly reliable. Here are a few reasons why. Neoprene is the most durable synthetic material for timing belts, and these 3 reasons should not discourage you from purchasing a new neoprene timing belt.

Neoprene timing belts are made of a high-quality chloroprene compound with a hardness of 74 Shore A. The high-strength glass fiber strands in the belt’s body transmit high power while enhancing its flexural strength. In addition, it’s covered with a high-strength polyamide fabric to reduce friction and protect contact surfaces from wear and tear.

Unlike neoprene, polyurethane synchronous belts are resistant to temperature and abrasion. Polyurethane timing belts are resistant to acids and chlorides, and exhibit excellent abrasion resistance. A neoprene belt can be used in high-speed applications, and can withstand extreme temperatures. However, the resistance of polyurethane to abrasion is not as good as that of neoprene.

The 2 most common types of timing belts are rubber and urethane. Rubber is the least expensive and quietest, and is the least flexible of the two. Neoprene is also highly elastic and does not retain its shape when it’s stretched, making it a popular choice for applications in manufacturing, agriculture, and robotics. They are also great for applications where precision and motion control are important. These properties make timing belts extremely effective in leading the industry toward its goals.

Chain timing belt

Traditionally, a vehicle’s timing system consists of a timing belt or chain. These components keep the engine’s intake and exhaust valves in the proper order. When these components go bad, it can ruin the engine in seconds. But there are advantages and disadvantages to each of them. Read on to learn about the pros and cons of each type of timing system. Here are some examples. Chain: A timing belt is generally made of reinforced rubber.

Chain: A timing chain is generally found in heavy-duty vehicles with higher torque. This type of timing belt is also found on many cars and SUVs with 4 cylinder engines that do not require a lot of torque. Unlike timing belts, timing chains are more durable and will last longer than their rubber counterparts. But there are certain things to keep in mind when replacing a timing belt. Make sure to change the oil regularly to avoid premature wear.