Product Description

High reliability has been achieved by special grease and high performance seal. We offers a wide line of bearings to meet the needs of every type of belt and layout…

Tensioner and Idler

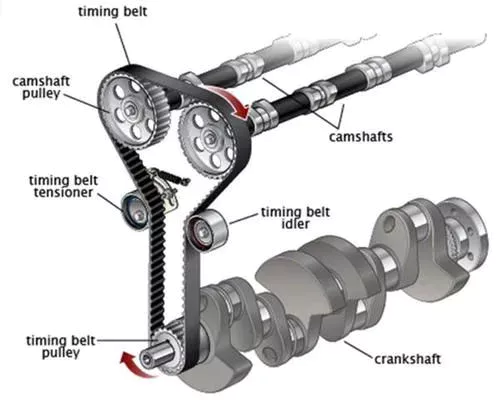

This bearing is located in the front of an internal combustion engine. It provides tension to the belt which drives from the crankshaft, to the cam shaft, alternator, air compressor, power steering pump, and water pump. It must handle high temperatures, high-speed rotation, and belt vibration because of contiguity in the engine used in order to make the direction of a belt change. These bearings are designed against different specification from normal deep groove bearings. These bearing are divided roughly into 2 types and identified by the usage, respectively.

1) Tensioner bearing

Bearing which applies tension to the drive belt, and prevents slack.

2) Idler bearing

Bearing which affects a change in the angle of direction which a belt runs or to adjust contact width with a pulley.

Structure

Sealed groove bearing is usually used and it also has built-in heat-resistant grease, a seal, and retainer and the structure can withstand a temperature change or change of belt tension when the car is running.

1)Tensioner bearing

The rotation center is movable in order to give tension to the belt.

2) Idler Bearing

Unitized with the pulley.

Product Function

The following are important functions of these indispensable parts for the smooth drive of the belt system.

1)To add initial tension by using the pivot hole and eccentric hole which absorb tension changes in the timing belt where the temperature changes when the engine is running.

2)To prevent any belt-skip, which would cause mis-matching of the valve timing between crank shaft and cam shaft

Construction of Tensioner and Idler pully bearing’s location in working

| SKF NO | NTN | NSK | ||||

| VKM12380 | VKM33 | 5JPU60-124+JF183 | 60TB0637 | |||

| VKM16 | JPU42-18 | 60TB039B09 | ||||

| VKM16101 | VKM71401 | VKM75130 | 2112-1 | JPU58-55 | 60TB048B01 | |

| VKM16210 | VKM72-01 | JPU58-015A-3 | 60TB041B12 | |||

| VKM22151 | VKM72 | JPU60-71+JF121 | 55TB0520B01 | |||

| VKM23240 | VKM73 | JPU60-260+JF397 | 50TB0524B03 | |||

| VKM23241 | VKM73011 | VKM75616 | F-226239.2 | JPU60-163+JF410 | 70TB0603 | |

| VKM241 | JPU55-30 | 52TB571B01 | ||||

| VKM24107 | VKM73112 | VKM76102 | F-231137 | JPU50- | NEP52-019A-1P | |

| VKM24211 | VKM74.05 | NEP57.6- | NEP62- | NEP57-013A-1P | ||

| VKM26101 | VKM74201 | VKM773 | NEP51-OO2B-6 | |||

| VKM26102 | VKM74501 | VKM77401 | F-140072 | NEP62-011A-1P | ||

| VKM26114 | VKM74600 | VKM77500 | OK247-12-711 | NEP52.8-002A-1P | ||

| VKM26123 | VKM75000 | VKM79001 | OK551-12-740A | NEP54-002-1P | ||

| VKM26125 | VKM75001 | VKM80000 | ||||

| VKM26211 | VKM75004 | VKM81001 | ||||

| VKM28000 | VKM75005 | VKM81002 | ||||

Five structure type as follows:

Nylon Pulley type;

Integrated type;

Steel Pulley with bracket type:

Steel Pulley Type;

Integrated with bracket type;

More timing belt tensioner bearings, pulley idler bearings, welcome to contact with us in details.

How to Tell If Your Timing Belt is Worn Out

The timing belt is a component of your engine that consists of special materials that coordinate the rotational movement of your camshaft and crankshaft. This synchronization is vital for sustainable combustion. In addition to being vital for the proper operation of your engine, the belt is also responsible for setting the pace at which it will turn. Timing belts must be extremely strong and resilient, able to maintain a high degree of synchronicity, and operate effectively even in the most severe conditions.

Problems caused by a worn-out timing belt

A worn-out timing belt can cause misfiring. Because the belt controls the movement of the pistons in the engine, it’s critical that it’s functioning properly. Misfires can cause serious engine damage and should be fixed as soon as possible. But how do you know if your timing belt is worn out? Here are 3 of the most common symptoms of a worn-out belt.

A car engine will misfire if the timing belt is broken, which could lead to severe damage. A broken belt may also cause excessive smoke to be produced by the exhaust system. If these symptoms are present, it’s time to take the car in for a timing belt replacement. A worn-out belt will affect the performance of your car. It will also affect the engine’s starting speed. When it’s time to replace it, you should do it now to avoid future problems.

Misfiring and premature cylinder closing are 2 of the most common symptoms of a worn-out timing belt. A worn-out belt can cause permanent engine damage. Because the timing belt contains teeth that grip the gears, it can slip. If the timing belt slips, the teeth can fall into the gears, causing the engine to misfire. Worn-out timing belts can also cause the engine to stall.

Engine ticking is another common sign of a worn-out timing belt. It can also be caused by low oil pressure. When oil pressure drops, the timing belt will become loose and cause a ticking sound. You should replace the timing belt as soon as it’s damaged. But it’s not enough if you don’t notice any of these signs right away. If the ticking sound continues, you’ll probably have an engine-related problem.

Types of timing belts

Timing belts are made of special materials that help the engine synchronize the crankshaft’s rotation with the camshaft’s. This precision is vital for the combustion process, as it ensures the proper opening and closing of the valves within the combustion chamber. The belts control the engine’s pace, which is why they must be strong enough to maintain synchronicity and operate at high speeds. However, timing belts do not come cheap, so there are several factors that you should be aware of before buying one.

First, timing belts come in different pitch sizes. A typical metric pitch is 5 millimeters, but some manufacturers use a higher or lower pitch. The pitch determines how much tension the belt will be able to carry and whether or not it will wear out prematurely. Other pitch sizes are more common. Timing belts come in 3 different widths, and they all have different tooth profiles. To find the right 1 for your engine, you need to know the pitch.

Modified curvilinear belts are made of 2 different types of materials. They combine the strengths of trapezoidal and curvilinear belts. The outer surface of these belts has a steeper angle than the belt’s teeth, which means that the power transmitted by the motor is much higher. Consequently, they are the primary choice for high-performance industrial applications. A synchronous timing belt is ideal for applications where precise synchronization of the driven and driver shafts is important.

Spliced and welded timing belts are used in many general applications. These belts typically have no joints or weak points and are more durable. These types of timing belts are also made with a smooth back and sealed edges. If you need a custom length or shape, these can also be manufactured. Then, you can order them for your exact measurements. When you need a new timing belt, you can simply ask for a quote and order 1 online.

Common problems

Timing belts are a crucial part of your car’s drive system, and improper installation can cause a whole host of issues. It is also susceptible to crimping and premature wear. In either case, it is vital to take action early to prevent excessive engine wear and extend the life of the timing belt. Here are some common problems with timing belts. You may be surprised to learn that these problems are often caused by common car maintenance practices.

Regardless of the cause of the problem, a worn or faulty timing belt will affect the engine’s timing. This may result in misfires or excessive exhaust release. Engine misfiring is a serious sign that something is amiss. Depending on the extent of the problem, it could even lead to engine damage. If you experience erratic performance or excessive smoke, it’s likely the timing belt is faulty. Here are some common problems with timing belts and their causes.

Engine misfire is a common warning sign that your timing belt is wearing. This occurs when the timing belt slips off the gears or camshaft, causing the cylinder to open too early. If you notice this problem, take immediate action by visiting your mechanic immediately. Moreover, timing belt failures can cause a large amount of damage to your car’s engine, so it is essential to have your timing belt replaced in time.

Improperly adjusting the tension of your timing belt can also lead to serious problems. This can cause excessive wear on your engine’s pistons and valves, and damage the engine. Ultimately, a damaged timing belt may result in an expensive engine rebuild. While this might seem like a good option, it is not always the most practical solution. Ultimately, your car’s timing belt will wear down if you don’t fix these problems immediately.

Symptoms of a worn-out timing belt

If your car’s engine makes a high-pitched squeal when you start or run it, you may be experiencing a worn-out timing belt. You can check the belt by opening the hood and listening closely to the noise. You may also notice uneven RPM counts. The squealing sound can be caused by a number of factors, such as low oil pressure, engine lubrication problems, or even the timing belt.

If your car is exhibiting these symptoms, then it’s time for a replacement. A timing belt breaks down while your engine is running, and this can cause major engine damage. The timing belt is connected to the crankshaft and camshaft by a belt that keeps the 2 parts in sync rotation. When the timing belt wears out, it may cause a jump in the belt’s tooth, causing cylinders to open and close randomly, resulting in blow-by.

A timing belt is crucial to the functioning of your car’s engine. It synchronizes the engine rotation system and opens and closes the valves at the right time. Because it is subject to great forces inside the engine, the belt must be replaced at some point. Every vehicle needs a new timing belt at least once in its lifecycle. But what are the symptoms of a worn-out timing belt?

The timing belt is crucial to your car’s performance, so if you notice any of these signs in your vehicle, you should make an appointment with a qualified mechanic. The best way to tell if your timing belt needs to be replaced is to visually inspect the belt. You can visually inspect the belt while the engine is off, and if you notice it’s sagging, you should replace it.

When to replace a timing belt

A timing belt is an essential part of your vehicle’s engine and is responsible for synchronizing the rotation system, allowing the valves to open and close at the correct time. Due to its constant use and great forces inside the engine, timing belts must be replaced at some point. The recommended interval for timing belt replacement is anywhere from 60,000 to 150,000 miles. In most cases, timing belt replacement is recommended for vehicles between 6 and 10 years old.

Costs for a timing belt replacement can vary widely depending on the make and model of your vehicle. The labour and parts used for timing belt replacement are relatively inexpensive, but you’ll have to remove several parts of your engine to access them. Timing belt replacement also involves replacing the water pump, which is driven by the timing belt. These other parts will be replaced with new ones, but the overall cost of the repair depends on the type of car you drive.

A timing belt is a thin, rubber piece that runs along the front of the engine. It’s responsible for synchronizing the valves and camshafts and is an important component of an engine. The belt’s custom teeth make it easy to see when it’s time to replace your car’s timing belt. Oftentimes, car manufacturers recommend timing belt replacement every 2 to 4 years or 50,000 miles, and they’re not the only ones who recommend it.

A professional mechanic can replace the timing belt and water pump in 1 service, saving you both time and money. Timing belt replacement is an intricate task and can last anywhere between 4 and 8 hours, depending on the make and model of your car. However, it is worth it if you can get your vehicle into a garage or repair shop sooner rather than later. You can save a lot of money on labor costs by replacing your timing belt and water pump yourself.