Product Description

Timing Pulley Toothed Synchronous Drives Pilot Bore Metric Pitch Sprocket Taper Bore 6 Inch V Belt Pulleys Wheels Sheave Suppliers Tensioner Automobile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the reliability and durability aspects of drive belt tensioners in ensuring consistent tension?

Reliability and durability are crucial aspects of drive belt tensioners in ensuring consistent tension in a belt-driven system. Tensioners play a critical role in maintaining proper belt tension, which directly impacts the system’s performance, efficiency, and longevity. Here’s a detailed explanation of the reliability and durability aspects of drive belt tensioners:

- Component Quality and Materials:

- Load Capacity and Design:

- Resistance to Environmental Factors:

- Proper Lubrication and Maintenance:

- Quality Assurance and Testing:

The reliability and durability of a drive belt tensioner heavily depend on the quality of its components and materials. High-quality tensioners are manufactured using robust materials that can withstand the stresses and environmental conditions encountered in automotive and industrial applications. Components such as bearings, pulleys, springs, and mounting brackets should be designed and constructed to withstand continuous operation, resist wear, and maintain their performance over time. Tensioners built with durable materials and precise manufacturing processes are less prone to premature failure, ensuring consistent tension for a longer duration.

The load capacity and design of a drive belt tensioner are vital considerations for reliability and durability. Tensioners should be appropriately sized and engineered to handle the tension forces exerted by the belt and the driven system. If the tensioner is undersized or poorly designed, it may experience excessive stress, leading to accelerated wear, deformation, or failure. Manufacturers provide load capacity specifications for tensioners, indicating the maximum tension they can handle. By selecting a tensioner with sufficient load capacity and a robust design, consistent tension can be maintained reliably over the life of the belt-driven system.

Drive belt tensioners are exposed to various environmental factors that can impact their reliability and durability. Factors such as temperature extremes, humidity, dust, and chemical contaminants can affect the performance of tensioners and their components. Reliable tensioners are designed and constructed to resist these environmental factors. They may incorporate special coatings, seals, or materials that provide protection against corrosion, abrasion, or degradation. By withstanding environmental challenges, tensioners can maintain their functionality and ensure consistent tension even in demanding operating conditions.

Appropriate lubrication and regular maintenance are essential for ensuring the reliability and durability of drive belt tensioners. Bearings and moving parts within the tensioner require proper lubrication to reduce friction, prevent excessive wear, and maintain smooth operation. Manufacturers often provide guidelines on the recommended lubrication intervals and types of lubricants to use. Regular maintenance, including inspections, cleaning, and replacement of worn components, helps identify potential issues early and prevent catastrophic failures. By following proper lubrication and maintenance practices, the tensioner’s reliability and durability can be maximized, ensuring consistent tension throughout its lifespan.

Reliable manufacturers of drive belt tensioners employ stringent quality assurance processes and testing procedures to ensure the durability and consistency of their products. These processes may include material testing, dimensional checks, load capacity verification, and performance testing under various conditions. Through rigorous quality control measures, manufacturers can identify and rectify any potential manufacturing defects or design flaws that could compromise the tensioner’s reliability. By choosing tensioners from reputable manufacturers with robust quality assurance practices, the risk of premature failures and inconsistent tension can be significantly reduced.

In summary, the reliability and durability of drive belt tensioners play a crucial role in ensuring consistent tension in a belt-driven system. High-quality components and materials, appropriate load capacity and design, resistance to environmental factors, proper lubrication and maintenance practices, and reliable manufacturing processes contribute to the long-term performance and reliability of tensioners. By selecting and maintaining reliable tensioners, consistent tension can be maintained, leading to optimal system performance, reduced downtime, and extended belt life.

What is the impact of proper tensioning on the lifespan and reliability of drive belts in automotive and industrial settings?

Proper tensioning has a significant impact on the lifespan and reliability of drive belts in both automotive and industrial settings. Maintaining the correct tension in drive belts is crucial for their optimal performance and longevity. Here’s a detailed explanation of the impact of proper tensioning on drive belts:

- Lifespan:

- Reliability:

- Reduced Maintenance:

- Optimal Performance:

Proper tensioning significantly extends the lifespan of drive belts. When a belt is under-tensioned, it can slip, especially under heavy loads or during sudden acceleration, deceleration, or changes in direction. Belt slippage causes excessive friction, heat, and wear, leading to premature belt failure. On the other hand, over-tensioning can put excessive stress on the belt, leading to accelerated wear, stretching, and potential damage. By maintaining the proper tension, drive belt tensioners ensure that the belt operates within its optimal range, reducing wear and extending the belt’s lifespan.

Proper tensioning enhances the reliability of drive belts. When a belt is properly tensioned, it maintains consistent contact with the pulleys, ensuring efficient power transmission. This minimizes the risk of belt slippage, which can result in power loss, reduced performance, and potential damage to the driven components. In automotive settings, reliable belt operation is crucial for the proper functioning of engine accessories like the alternator, power steering pump, and air conditioning compressor. In industrial settings, reliable belt operation ensures uninterrupted power transmission and prevents costly downtime. By maintaining proper tension, drive belt tensioners play a vital role in ensuring the reliable operation of drive belts in automotive and industrial applications.

Proper tensioning can reduce the need for frequent belt adjustments and maintenance. When a belt is properly tensioned, it experiences minimal wear and stretching, reducing the frequency of tension adjustments. This saves time and effort in maintaining the belt system. In automotive settings, it means that the serpentine belt system can operate for longer intervals without requiring manual tension adjustments. In industrial settings, drive belts can operate more reliably and require fewer shutdowns for tensioning adjustments. By reducing maintenance requirements, proper tensioning contributes to improved efficiency and productivity in automotive and industrial applications.

Proper tensioning ensures optimal performance of drive belts. When a belt is correctly tensioned, it maintains proper engagement with the pulleys, allowing efficient power transfer. This optimizes the performance of driven components, such as alternators, pumps, and compressors. In automotive settings, proper belt tensioning helps ensure reliable operation of engine accessories, maintaining electrical charging, power steering, and air conditioning functions. In industrial settings, optimal belt tensioning ensures efficient power transmission, minimizing energy losses and maximizing the performance of machinery and equipment. By maintaining optimal performance, proper tensioning enhances the overall efficiency and functionality of drive belts in automotive and industrial applications.

In summary, proper tensioning has a significant impact on the lifespan and reliability of drive belts in automotive and industrial settings. It extends the belt’s lifespan, enhances reliability, reduces maintenance requirements, and ensures optimal performance. Drive belt tensioners play a crucial role in maintaining the proper tension of belts, contributing to the longevity and efficient operation of drive belts in various applications.

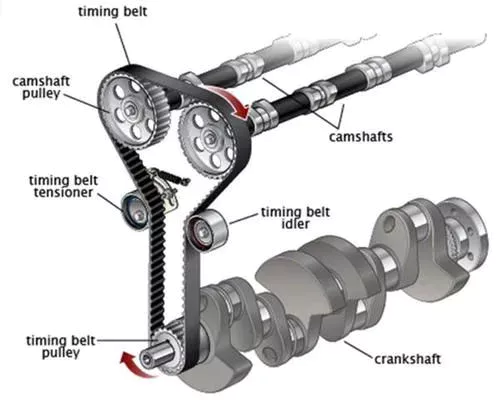

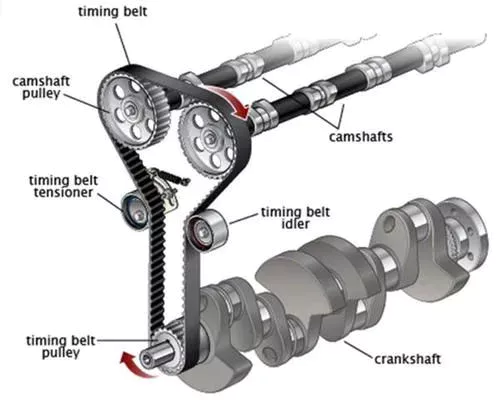

What is a drive belt tensioner, and how does it function in automotive and industrial applications?

A drive belt tensioner is a mechanical component used in automotive and industrial applications to maintain proper tension in the drive belt system. It is designed to ensure that the belt remains tight and properly engaged with the pulleys, allowing for efficient power transmission. Here’s a detailed explanation of what a drive belt tensioner is and how it functions:

- Definition and Components:

- Function in Automotive Applications:

- Function in Industrial Applications:

- Functioning Mechanism:

- Benefits and Importance:

A drive belt tensioner, also known as a belt tensioner or a serpentine belt tensioner, is typically a spring-loaded or hydraulic mechanism that exerts constant tension on the drive belt. It consists of several components, including a tensioner pulley, an arm or bracket, a spring or hydraulic cylinder, and a pivot point. The tensioner pulley is responsible for applying tension to the belt, while the arm or bracket holds the pulley in place. The spring or hydraulic cylinder provides the force necessary to maintain tension, and the pivot point allows for movement and adjustment.

In automotive applications, drive belt tensioners are commonly used in the serpentine belt system. The serpentine belt is a single, long belt that drives various engine accessories, such as the alternator, power steering pump, air conditioning compressor, and water pump. The tensioner ensures that the serpentine belt remains properly tensioned, preventing slippage and ensuring efficient power transfer to these accessories. It compensates for belt stretch, wear, and load variations, maintaining consistent tension and optimizing the performance of the engine accessories.

In industrial applications, drive belt tensioners are employed in various belt drive systems. These systems may include multiple belts, such as V-belts or timing belts, driving different components in machinery or equipment. The tensioner’s role is to maintain proper tension in each belt, ensuring reliable power transmission and preventing slippage. It adapts to load variations, compensates for belt stretch and wear, and helps distribute the load evenly among the belts. By maintaining optimal tension, drive belt tensioners enhance the overall efficiency, reliability, and lifespan of the belt drive systems in industrial applications.

The functioning of a drive belt tensioner depends on its specific design, which can vary depending on the application and the type of tensioner used. In general, tensioners utilize the force generated by a spring or hydraulic cylinder to exert tension on the belt. The tensioner is typically mounted on an adjustable arm or bracket, allowing for movement and adjustment to maintain the desired tension. As the belt stretches or wears over time, the tensioner compensates by applying additional tension to keep the belt properly engaged with the pulleys. Some tensioners incorporate automatic self-adjustment mechanisms, while others may require manual adjustment or periodic inspection to ensure proper tension.

Drive belt tensioners offer several benefits and play a crucial role in automotive and industrial applications. They prevent slippage, optimize power transmission, and maintain consistent tension in the belt drive systems. By compensating for belt stretch, wear, and load variations, tensioners ensure reliable and efficient operation of the driven components. They reduce the risk of belt failure, minimize wear and fatigue, and extend the lifespan of the belts. Proper tensioning provided by drive belt tensioners enhances overall system performance, reduces maintenance requirements, and increases the reliability and longevity of the belt drive systems.

In summary, a drive belt tensioner is a mechanical component that maintains proper tension in the drive belt system. It functions by applying tension to the belt using a pulley, spring, or hydraulic cylinder. In automotive applications, tensioners optimize power transmission in the serpentine belt system, while in industrial applications, they ensure reliable power transfer in various belt drive systems. By compensating for belt stretch, wear, and load variations, drive belt tensioners enhance efficiency, reduce wear, and extend the lifespan of the belts, contributing to the overall performance and reliability of automotive and industrial machinery.

editor by CX 2024-04-10

China Conveyor System Manufacturer Conveyor Rollers Conveyor Drum Pulleys chain pulley

Product Description

Double Arrow Conveyor Roller description:

Conveyor rollers&lparidlers) are crucial parts on Belt Conveyor, it endure more than 70&percnt resistance of 1 belt conveyor. The conveyor roller&lparidler) utilised for supporting conveyor belt and the substance. There are varieties roller we equipped, like metal, nylon, ceramic or rubber. With a long time planning and manufacturing knowledge CZPT turns into a high good quality roller&lparidler) server in conveyor spares business.

Summary of the conveyor roller information:

| Substance: | metal, nylon, SS, ceramic,pvc,UHMWPE,HDPE |

| Bearing Product: | 6204,6205,6305,6306,6307,6308 |

| Bearing Brand: | HRB, LYC, ZWZ,SKF, NSK,C&U |

| Operating Existence: | &geq30000 hrs |

| Diameter: | D38mm to D219mm |

| Belt Width: | B450mm to B2200mm |

| Software: | recycling business electrical power industry parcel transportation business petro business coal mining sector cement concrete business machining sector |

| Unique: | can be custom-made in accordance to customer or design and style for client |

| Provide Capability: | 1000pcs for every working day |

| Certificate: | ISO9001:2008, BV, SGS |

Software:

The items are widely employed in coal mines, metallurgy, equipment, ports, building, electrical power, chemistry, foods packing and other industries.

Other information:

Double Arrow acquired the ISO9001: 2008 in2571, and with ten several years developing and manufacturing expertise . CZPT items are very good conveyor program brand name in China .

Double Arrow Conveyor technique projects

one. The optimum stage of customer services, competitive pricing, speedy shipping and delivery and a extensive, chopping-edge item providing are our basic missions, your gratification is our supreme aim.

2. Personalized Items are very welcome

three. Free of charge Sample is available

If you have any issues for the unit cost and shipping and delivery value, pls send out us email, we shall supply you greatest price tag record.

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Rubber Coat, PU Coat, Static Spray Painting |

| Installation: | Welding or Slot Mounted |

| Brand: | Double Arrow |

| Roller Dia.: | D60-D219 mm |

| Roller Length: | Less Than 3000mm |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material: | steel, nylon, SS, ceramic,pvc,UHMWPE,HDPE |

| Bearing Model: | 6204,6205,6305,6306,6307,6308 |

| Bearing Brand: | HRB, LYC, ZWZ,SKF, NSK,C&U |

| Working Life: | ≥30000 hours |

| Diameter: | D38mm to D219mm |

| Belt Width: | B450mm to B2200mm |

| Application: | recycling industry power industry parcel transport industry petro industry coal mining industry cement concrete industry machining industry |

| Special: | can be customized according to customer or design for customer |

| Supply Ability: | 1000pcs per day |

| Certificate: | ISO9001:2008, BV, SGS |

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Rubber Coat, PU Coat, Static Spray Painting |

| Installation: | Welding or Slot Mounted |

| Brand: | Double Arrow |

| Roller Dia.: | D60-D219 mm |

| Roller Length: | Less Than 3000mm |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material: | steel, nylon, SS, ceramic,pvc,UHMWPE,HDPE |

| Bearing Model: | 6204,6205,6305,6306,6307,6308 |

| Bearing Brand: | HRB, LYC, ZWZ,SKF, NSK,C&U |

| Working Life: | ≥30000 hours |

| Diameter: | D38mm to D219mm |

| Belt Width: | B450mm to B2200mm |

| Application: | recycling industry power industry parcel transport industry petro industry coal mining industry cement concrete industry machining industry |

| Special: | can be customized according to customer or design for customer |

| Supply Ability: | 1000pcs per day |

| Certificate: | ISO9001:2008, BV, SGS |

Pulley Type

There are several types of pulleys. These include fixed pulleys, load multipliers and movable pulleys. Below is a description of each pulley type. A load multiplier is a special type of pulley with multiple wheels for increased lifting capacity. It is used in a wide range of applications including power transmission and construction. Some common uses of pulleys are listed below.

moving pulley

Movable pulleys work by transferring the weight of a load to another object of the same mass. Since a live pulley is inherently frictionless and weightless, the force required to lift a load with it is the same as the weight of the load. This principle applies to tall buildings and residences. It is an excellent choice for lifting heavy objects such as furniture and washing machines.

A pulley is a mechanical device with a wheel that rotates on a shaft. The axle is attached to the wheel and is usually fixed. The movable pulley can be fixed or movable, both of which can change the direction of the force on the rope. Some pulleys can also change the magnitude and direction of the force. They are ideal for a variety of applications, from lifting heavy objects to transporting objects.

Another type of movable pulley works by transmitting force to another object. It has a free axis and the total force provided by the rope tension is balanced. Since the tension on the rope is constant in each segment, pulling one end of the rope will double the force on the shaft, resulting in two mechanical advantages. This mechanical advantage is the main reason why movable pulleys are so versatile.

Another form of moving pulley is called a KWL diagram. The KWL diagram summarizes the basic concepts of the drive wheel. KWL diagrams are an excellent way to assess a student’s understanding of the concepts discussed in the course. Word questions are a great way to check whether students understand concepts. When students answer the word questions correctly, the answer is yes!

Fixed wheel pulley

If you need to move heavy objects, a single fixed wheel pulley is not a good choice. Using a single fixed pulley might be similar to using a handbag, but it’s not very convenient. This type of pulley system relies on friction to transmit motion. As a result, it can slip and isn’t always reliable. Fortunately, you can find other options that work just as well.

Fixed pulleys are the most basic type of pulley. They consist of grooved wheels and ropes attached to objects. These pulleys make lifting easier. Because the rope or cable only moves in one direction, the movement of the object feels lighter. And they are also easy to install. However, before you buy a fixed wheel pulley, make sure it is strong enough to support the weight of the load.

The disadvantages of fixed pulleys are obvious. One of them is the lack of mechanical advantage. A fixed pulley pulls up with the same force as a single moving pulley, and a single fixed pulley is not particularly effective as a force multiplier. However, the effect is more pronounced when you combine multiple fixed-wheel pulleys. You will get double the power! So what do fixed wheel pulleys have to offer?

Fixed wheel pulleys can be as small as a ring. A single ring pulley requires twice as much force as the weight being pulled. Adding more loops to the rope will reduce the effort required to pull the weight. The mechanical advantage of a fixed pulley is proportional to the number of strands running to the free pulley. A 100-pound pull on the free end will lift a 300-pound load.

composite pulley

Compound pulleys are pulleys that can be used to change the direction of a control wire. It can also be used to modify the mechanical force of the wire by moving the item it is connected to. In galleons, compound pulleys are more common. They are often combined with other ropes for mechanical advantage. Here are some common uses for composite pulleys.

The ideal mechanical advantage of a pulley is equal to the number of rope segments that pull up the load. This means that the more rope segments, the less force is required. A compound pulley will have the ideal mechanical advantage of 2, which means it will generate more force than a simple pulley. Composite pulleys are also more efficient at transmitting force because their number of rope segments is usually equal to the unit weight.

Composite pulley systems use more than two pulleys and ropes. More pulleys will reduce the force required to move heavier objects. They are usually used in large sailboats. The system is also used on construction sites. It can be used for a variety of applications, including lifting large objects or transmitting electricity. You can imagine how it would change your life if you had to move a large sailboat, but the result would be the same: a composite pulley system would make it easier to lift a large sailboat.

Composite pulleys are also known as fixed pulleys. The fixed pulley is stationary, and the movable pulley moves back and forth. The latter is more effective when used with a detachable cord or strap. On the other hand, a moving pulley is a moving pulley and it gives you a mechanical advantage. You can imagine this pulley on a flagpole.

load multiplier

The multiplication system has three basic parts: the rope grab, the connector, and the pulley. While some basic multipliers may combine the three parts, the concept remains the same. The multiplication system can make pulling the rope easier by reducing the amount of friction that occurs. Below are some examples of multiplication systems. A compact rope grab is a great option for resetting the multiplier.

The load reduction that a pulley system can achieve is proportional to the number of ropes used to support it. Although most utility pulley systems use only four ropes, the theoretical maximum load reduction is a quarter of the actual load. In other words, the four-wheel system only reduces the weight of a 1,000-pound load by a quarter. That would require 167 pounds of force, a far cry from the 500-pound load a single pulley system can achieve.

The mechanical advantage of a pulley system can be calculated by calculating the ratio between the forces exerted on each wire. For example, a 90-kilogram load is supported by three ropes, each weighing about thirty-five pounds. The ropes on pulleys A and B each carry a load of 60 kg. Using this formula, a single pulley system will yield a mechanical advantage over two tractors.

To calculate the force required to pull the rope over the pulley, measure the angle and deflection between the ropes. The deflection angle when added to the included angle should equal 180 degrees. A 75 degree angle requires 159% of the load force. This means a total load multiplier of four. This formula is an important tool for calculating the force multiple of the pulley.

Disadvantages of fixed pulleys

There are two basic types of pulleys: movable and fixed. Active pulleys are more advanced, allowing the pulley to move according to the load. They reduce the force required to lift the load. Active roller pulleys are more compact and therefore take up less space. Both types are good for lifting heavier objects, but they each have their pros and cons.

Fixed wheel pulleys can be used to lift heavy objects. This type of pulley consists of a wheel with a fixed shaft that has grooves on its edges for guiding ropes or cables. This is a simple machine as no motor or engine is required to lift objects. When two or more wheels are used together, the ropes around the wheels form a powerful hoist.

Single wheel pulleys are not suitable for lifting. They tend to push things down. Also, they are unreliable because they rely on friction and can slip. Also, a single wheel pulley would require a lot of space. Another disadvantage of fixed-wheel pulleys is that they make it difficult to move heavy objects easily. Single fixed-wheel pulleys also tend to slip easily, making them a poor choice for many applications.

Fixed wheel pulleys are also easier to install and maintain than manually operated ones. It requires less space and lubrication than manual pulleys. Manual pulleys can cause injury because the operator will be lifting the full weight of the heavy object. Additionally, rope slippage can lead to muscle strains and rope burns. And the system requires frequent maintenance.

editor by czh 2023-01-04

China 24t5-20al Aluminium Timing Pulleys alternator pulley

Merchandise Description

CZPT Machinery gives a vast assortment of large top quality Timing Belt Pulleys and Toothed Bars/ Timing Bars. Normal and non-common pulleys in accordance to drawings are offered.

Kinds of substance:

1. AlCuMgPb 6061 6082 Aluminum Timing Pulley

2. C45E 1045 S45C Carbon Metal Timing Pulley

3. GG25 HT250 Solid Iron Timing Pulley

4. SUS303 SUS304 AISI431 Stainless Metal Timing Pulley

5. Other materials on demand from customers, these kinds of as cooper, bronze and plastic

Kinds of surface area treatment method

1. Anodized area -Aluminum Pulleys

2. Hard anodized surface — Aluminum Pulleys

3. Black Oxidized surface — Steel Pulleys

4. Zinc plated floor — Steel Pulleys

5. Chromate area — Steel Pulleys Cast Iron Pulleys

6. Nickel plated area –Metal Pulleys Forged Iron Pulleys

Types of enamel profile

| Teeth Profile | Pitch |

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | .08″(2.032MM) |

| XL | one/5″(5.08MM) |

| L | three/8″(9.525MM) |

| H | one/2″(twelve.7MM) |

| XH | seven/8″(22.225MM) |

| XXH | one 1/4″(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

Kinds of pitches and measurements

Imperial Inch Timing Belt Pulley,

one. Pilot Bore MXL571 for 6.35mm timing belt teeth quantity from sixteen to seventy two

two. Pilot Bore XL037 for 9.53mm timing belt enamel variety from 10 to 72

3. Pilot Bore, Taper Bore L050 for twelve.7mm timing belt tooth amount from 10 to one hundred twenty

four. Pilot Bore, Taper Bore L075 for 19.05mm timing belt tooth quantity from 10 to a hundred and twenty

5. Pilot Bore, Taper Bore L100 for twenty five.4mm timing belt tooth amount from 10 to a hundred and twenty

6. Pilot Bore, Taper Bore H075 for 19.05mm timing belt teeth number from fourteen to 50

seven. Pilot Bore, Taper Bore H100 for 25.4mm timing belt teeth variety from fourteen to 156

8. Pilot Bore, Taper Bore H150 for 38.1mm timing belt teeth variety from 14 to 156

9. Pilot Bore, Taper Bore H200 for 50.8mm timing belt enamel variety from fourteen to 156

10. Pilot Bore, Taper Bore H300 for 76.2mm timing belt tooth number from fourteen to 156

eleven. Taper Bore XH200 for 50.8mm timing belt enamel amount from 18 to a hundred and twenty

12. Taper Bore XH300 for seventy six.2mm timing belt teeth variety from 18 to 120

thirteen. Taper Bore XH400 for one zero one.6mm timing belt enamel number from 18 to a hundred and twenty

Metric Timing Belt Pulley T and AT

1. Pilot Bore T2.5-16 for 6mm timing belt teeth amount from twelve to 60

2. Pilot Bore T5-21 for 10mm timing belt teeth variety from ten to 60

3. Pilot Bore T5-27 for 16mm timing belt tooth amount from ten to 60

four. Pilot Bore T5-36 for 25mm timing belt tooth quantity from 10 to 60

5. Pilot Bore T10-31 for 16mm timing belt tooth number from twelve to 60

six. Pilot Bore T10-40 for 25mm timing belt tooth number from twelve to 60

7. Pilot Bore T10-47 for 32mm timing belt tooth quantity from eighteen to 60

8. Pilot Bore T10-66 for 50mm timing belt enamel quantity from 18 to sixty

nine. Pilot Bore AT5-21 for 10mm timing belt enamel amount from 12 to 60

ten. Pilot Bore AT5-27 for 16mm timing belt tooth amount from twelve to sixty

11. Pilot Bore AT5-36 for 25mm timing belt tooth amount from 12 to 60

12. Pilot Bore AT10-31 for 16mm timing belt teeth number from fifteen to 60

thirteen. Pilot Bore AT10-40 for 25mm timing belt teeth number from 15 to 60

fourteen. Pilot Bore AT10-47 for 32mm timing belt teeth number from 18 to 60

fifteen. Pilot Bore AT10-66 for 50mm timing belt teeth amount from eighteen to 60

Metric Timing Belt Pulley HTD3M, 5M, 8M, 14M

one. HTD3M-06 3M-09 3M-15 teeth number from ten to 72

2. HTD5M-09 5M-15 5M-twenty five enamel amount from 12 to 72

3. HTD8M-20 8M-thirty 8M-fifty 8M-eighty five enamel number from 22 to 192

4. HTD14M-40 14M-55 14M-eighty five 14M-one hundred fifteen 14M-a hundred and seventy teeth quantity from 28-216

5. Taper Bore HTD5M-15 8M-20 8M-30 8M-fifty 8M-eighty five 14M-40 14M-fifty five 14M-eighty five

14M-115 14M-170

Metric Timing Belt Pulleys for Poly Chain GT2 Belts

1. PCGT8M-twelve PCGT8M-21 PCGT8M-36 PCGT8M-62

2. PCGT14M-twenty PCGT14M-37 PCGT14M-68 PCGT14M-ninety PCGT14M-a hundred twenty five

Energy Grip CZPT Tooth/ PGGT 2GT, 3GT and 5GT

one. 2GT-06, 2GT-09 for timing belt width 6mm and 9mm

two. 3GT-09, 3GT-fifteen for timing belt width 9mm and 15mm

three. 5GT-fifteen, 5GT-25 for timing belt width 15mm and 25mm

OMEGA RPP HTD Timing Pulleys

one. RPP3M-06 3M-09 3M-15 tooth variety from 10 to 72

two. RPP5M-09 5M-15 5M-25 teeth amount from twelve to 72

three. RPP8M-twenty 8M-30 8M-50 8M-eighty five enamel variety from 22 to 192

4. RPP14M-forty 14M-fifty five 14M-eighty five 14M-one hundred fifteen 14M-one hundred seventy tooth number from 28-216

five. Taper Bore RPP5M-fifteen 8M-20 8M-30 8M-50 8M-eighty five 14M-40 14M-fifty five 14M-eighty five

14M-one hundred fifteen 14M-a hundred and seventy

|

US $0.5-50 / Piece | |

10 Pieces (Min. Order) |

###

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Timing |

| Manufacturing Process: | Sawing |

| Material: | Aluminum 6082 |

| Surface Treatment: | Phosphating |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

###

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Teeth Profile | Pitch |

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | 0.08"(2.032MM) |

| XL | 1/5"(5.08MM) |

| L | 3/8"(9.525MM) |

| H | 1/2"(12.7MM) |

| XH | 7/8"(22.225MM) |

| XXH | 1 1/4"(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

|

US $0.5-50 / Piece | |

10 Pieces (Min. Order) |

###

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Timing |

| Manufacturing Process: | Sawing |

| Material: | Aluminum 6082 |

| Surface Treatment: | Phosphating |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

###

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Teeth Profile | Pitch |

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | 0.08"(2.032MM) |

| XL | 1/5"(5.08MM) |

| L | 3/8"(9.525MM) |

| H | 1/2"(12.7MM) |

| XH | 7/8"(22.225MM) |

| XXH | 1 1/4"(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

Calculate the ideal mechanical advantage of pulleys

The basic equations for pulleys can be found in this article. It will also cover the different types of pulleys, the ideal mechanical advantages of pulleys, and some common uses of pulley systems. Read on to learn more! After all, a pulley is a simple mechanical device that changes the direction of a force. Learn more about pulleys and their common uses in engineering.

pulley basic equation

Pulleys work the same way as gravity, so they should withstand similar forces. Newton’s laws of motion can be used to calculate the forces in a pulley system. The second law of motion applies to forces and accelerations. Similar to this is Newton’s third law, which states that the directions of forces are equal and opposite. The fourth law dictates the direction of force. The Fifth Law states that tension is in equilibrium with gravity.

A pulley is a simple mechanism that transmits force by changing direction. They are generally considered to have negligible mass and friction, but this is only an approximation. Pulleys have different uses, from sailboats to farms and large construction cranes. In fact, they are the most versatile mechanisms in any system. Some of their most common applications and equations are listed below.

For example, consider two masses m. Those of mass m will be connected by pulleys. The static friction coefficient of the left stop is ms1, and the static friction coefficient of the right stop is ms2. A no-slip equation will contain multiple inequalities. If the two blocks are considered to be connected by a pulley, the coefficient of kinetic friction is mk. In other words, the weight of each block carries the same mass, but in the opposite direction.

Types of pulleys

A pulley is a device used to pull and push objects. Pulley systems are ropes, cables, belts or chains. The “drive pulley” is attached to the shaft and moves the driven pulley. They are available in a variety of sizes, and the larger they are, the higher the speed of power transmission. Alternatively, use small pulleys for smaller applications.

Two-wheel pulleys have two mechanical advantages. The greater the mechanical advantage, the less force is required to move the object. More wheels lift more weight, but smaller pulleys require less force. In a two-wheel pulley system, the rope is wound around two axles and a fixed surface. As you pull on the rope, the shafts above slowly come together.

Compound pulleys have two or more rope segments that are pulled up on the load. The mechanical advantage of compound pulleys depends on the number of rope segments and how they are arranged. This type of pulley can increase the force by changing the direction of the rope segment. There are two main types of pulleys. Composite pulleys are most commonly used in construction. The ideal mechanical advantage of pulleys is 2 or more.

Construction pulleys are a basic type. They are usually attached to wheel rails and can be lifted to great heights. Combinations of axes are also common. Construction pulleys can be raised to great heights to access materials or equipment. When used in construction, these pulleys are usually made of heavy materials such as wood or metal. They are secured with ropes or chains.

The ideal mechanical advantage of pulleys

The pulley system is a highly complex system with high mechanical advantages. Use a single pulley system to reduce the force required to lift an object by cutting it in half. The mechanical advantage increases as you add more pulleys, such as six or seven. To calculate the mechanical advantage of a pulley system, you need to count the number of rope segments between the pulleys. If the free end of the rope is facing down, don’t count it. If it’s facing up, count. Once you have your number, add it up.

The required mechanical advantage of a pulley is the number of rope segments it has to pull the load. The more rope segments, the lower the force. Therefore, the more rope segments the pulley has, the lower the force. If the rope segments are four, then the ideal mechanical advantage is four. In this case, the composite pulley quadrupled the load force.

The ideal mechanical advantage of a pulley system is the sum of the mechanical force and the force required to lift the load at its output. Typically, a single pulley system uses two ropes, and the mechanical force required to lift the load is multiplied by the two ropes. For a multi-pulley system, the number of ropes will vary, but the total energy requirement will remain the same. The friction between the rope and pulley increases the force and energy required to lift the load, so the mechanical advantage diminishes over time.

Common uses of pulley systems

A pulley system is a simple mechanical device typically used to lift heavy objects. It consists of a rotating wheel attached to a fixed shaft and a rope attached to it. When the wheel moves, the force applied by the operator is multiplied by the speed of the pulley, and the force is multiplied by the weight of the object being lifted. Common uses for pulley systems include pulling, lifting, and moving heavy objects.

The oil and petroleum industries use pulley systems in a variety of applications. Most commonly, pulleys are used in drilling operations and they are installed on top of the rig to guide the cable. The cable itself is attached to two pulleys suspended in the derrick, where they provide mechanical energy to the cable. Using a pulley system in this application provides the force needed to move the cable safely and smoothly.

The main advantage of the pulley system is that it minimizes the force required to lift an object. The force used to lift the object is multiplied by the desired mechanical advantage. The more rope segments, the lower the force required. On the other hand, a compound pulley system can have many segments. Therefore, a compound pulley system can increase the force a worker can exert on an object.

Safety Precautions to Take When Working on Pulley Systems

There are many safety precautions that should be observed when working on a pulley system. The first is to wear proper protective gear. This includes hard hats that protect you from falling objects. Also, gloves may be required. You should limit the amount of movement in the penalty area, and you should also keep the area free of unnecessary people and objects. Also, remember to wear a hard hat when working on the pulley system.

Another important safety precaution when working on a pulley system is to check the Safe Working Load (SWL) of the pulley before attaching anything. This will help you understand the maximum weight the pulley can hold. Also, consider the angle and height of the pulley system. Always use safety anchors and always remember to wear a hat when working on a pulley system.

Safe use of chain hoists requires training and experience. It is important to read the manufacturer’s manual and follow all safety precautions. If you’re not sure, you can actually inspect the hoist and look for signs of damage or tampering. Look for certifications for sprocket sets and other lifting accessories. Look for the Safe Working Load (SWL) marking on the chain hoist.

Example of a pulley system

Pulley systems are often used to lift items. It allows you to reduce the effort to lift and move the load by applying force in one direction. Pulley systems can be built and modeled to fit any type of project. This resource focuses on pulley systems and is designed to support the new GCSEs in Engineering, Design and Technology. There are also many examples of pulley systems suitable for various applications.

In the study, participants who read easy text took longer to manipulate the pulley system than those who read challenging text. In general, this suggests that participants with prior scientific experience used their cognitive abilities more effectively. Additionally, students who read simple texts spent less time planning the pulley system and more time on other tasks. However, the study did show that the time required to plan the pulley system was similar between the two groups.

In everyday life, pulley systems are used to lift various objects. Flagpoles are one of many pulley systems used to raise and lower flagpoles. They can also be used to raise and lower garage doors. Likewise, rock climbers use pulleys to help them ascend and descend. The pulley system can also be used to extend the ladder.

editor by czh 2022-12-21

China Belt Pulley Belt Pulleys Gear Belt Pulley with Tooth chain pulley

Product Description

Product Description

|

Solution Identify |

belt tensioner pulley |

|

OEM No. |

Standard |

|

MOQ |

10PCS |

|

Package |

Neutral box,Personalized box |

|

Good quality |

Good quality |

|

Shipping Port |

Normally in HangZhou Port. The port specified by the consumer is acceptable. |

|

Sample |

Obtainable |

|

Shipment |

By sea or by express(DHL,TNT,Fedex and EMS etc.) |

|

Warranty |

1 12 months |

|

Stock |

5000 PCS |

Certifications

Packaging & Transport

Organization Profile

HangZhou HangZhou Auto Components Co., Ltd. was proven in 1999, located in HangZhou, ZHangZhoug, with lovely landscapes and hassle-free transportation! The business was previously identified as HangZhoung, HangZhou, and formally modified its title to HangZhou. The business addresses the whole auto elements with cooling method, steering chassis method, suspension method, braking technique, ignition method, fasteners,and many others. In-depth cooperation with many massive domestic factories, our products are exported to residence and overseas! Regardless of whether you pick the present item from the catalog or personalize it for you, we can meet your requirements! We have a pursuit of CZPT in merchandise quality!

20 many years of industry refining, we have uncovered too significantly. We abide by the integrity of company, serve with heart, often get buyer satisfaction as the axis, consider, consider action, develop genuine worth for buyers, exchange heart with customers, go hand in hand Acquire-get scenario!

Our philosophy and purpose are: primarily based on integrity, sincere provider, the pursuit of excellence, return to modern society, believe and realize, recognize and act, and go high!

Our Benefits

FAQ

Q1. How a lot of several years does your company trade in vehicle components?

A: We have been set up for Much more than 20 several years.

Q2. In which is your business?

A: We are positioned in ZHangZhoug

Q3. What is the delivery day?

A: If it requires 5~7 times for inventory, it will take twenty-40 times if there is no inventory.

Q4. What is a package deal?

A: Neutral packaging or buyer packaging.

Q5. What is the payment method?

A: Our payment technique: T / T

Q6. What is the payment phrases?

A: Our payment conditions: Following entire payment

Q7. How is the high quality?

A: Rigorous management just before shipment.

Q8. What is a guarantor?

A: 12 months.

Q9. Can you aid with the supply of the products?

A: Indeed. We can help supply goods by means of our customer freight forwarders or our freight forwarders.

Q10. Can you provide samples for cost-free?

A: It relies upon on the price of the sample, but we do not pay out the delivery price.

Q11. Which port does our organization provide?

A: Normally in HangZhou Port. The port specified by the buyer is acceptable.

| Type: | Wheel Hub Bearing |

|---|---|

| Material: | Stainless Steel |

| Tolerance: | P4 |

| Certification: | ISO9001 |

| Clearance: | C3 |

| ABS: | With ABS |

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

belt tensioner pulley

|

|

OEM No.

|

Standard

|

|

MOQ

|

10PCS

|

|

Package

|

Neutral box,Customized box

|

|

Quality

|

Good quality

|

|

Shipping Port

|

Usually in Ningbo Port. The port specified by the customer is acceptable.

|

|

Sample

|

Available

|

|

Shipment

|

By sea or by express(DHL,TNT,Fedex and EMS etc.)

|

|

Warranty

|

1 year

|

|

STOCK

|

5000 PCS

|

| Type: | Wheel Hub Bearing |

|---|---|

| Material: | Stainless Steel |

| Tolerance: | P4 |

| Certification: | ISO9001 |

| Clearance: | C3 |

| ABS: | With ABS |

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

belt tensioner pulley

|

|

OEM No.

|

Standard

|

|

MOQ

|

10PCS

|

|

Package

|

Neutral box,Customized box

|

|

Quality

|

Good quality

|

|

Shipping Port

|

Usually in Ningbo Port. The port specified by the customer is acceptable.

|

|

Sample

|

Available

|

|

Shipment

|

By sea or by express(DHL,TNT,Fedex and EMS etc.)

|

|

Warranty

|

1 year

|

|

STOCK

|

5000 PCS

|

The importance of pulleys

A pulley is a wheel that rides on an axle or axle. The purpose of the pulley is to change the direction of the tensioning cable. The cable then transfers the power from the shaft to the pulley. This article explains the importance of pulleys and demonstrates several different uses for this machine. Also, see the Mechanical Advantages section below for the different types. let’s start.

simple machine

A simple pulley machine is a device used to transfer energy. It consists of a wheel with flexible material on the rim and a rope or chain tied to the other end. Then lift the load using the force applied to the other end. The mechanical advantage of this system is one, as the force applied to the load is the same as the force on the pulley shaft.

A simple pulley machine has many benefits, from the ability to build pyramids to building modern buildings with it. Pulleys are also popular with children because they can perform simple tasks such as lifting toys onto a slide, sliding them off the slide, and lifting them up again. These activities, called “transportation” by child development theorists, allow them to learn about the physics of simple machines in the process.

The mechanism works by using cables to transmit force. The cable is attached to one side of the pulley and the other side is pulled by the user. Lift the load by pulling on one end and the other end of the rope. Simple pulley machines have many commercial and everyday applications, including helping move large objects. They can be fixed or movable, and can be a combination of both. The present invention is a great tool for any beginner or engineer.

axis

The axle wheel is the basic mechanical part that amplifies the force. It may have originally appeared as a tool to lift buckets or heavy objects from a well. Its operation is demonstrated by large and small gears attached to the same shaft. When applied to an object, the force on the large gear F overcomes the force W on the pinion R. The ratio of these two forces is called the mechanical advantage.

The ideal mechanical advantage of shaft pulleys is their radius ratio. A large radius will result in a higher mechanical advantage than a small radius. A pulley is a wheel through which a rope or belt runs. Often the wheels are interconnected with cables or belts for added mechanical advantage. The number of support ropes depends on the desired mechanical advantage of the pulley.

In the design of the axle wheel, the axle is the fulcrum and the outer edge is the handle. In simple terms, wheels and axle pulleys are improved versions of levers. The axle pulley moves the load farther than the lever and connects to the load at the center of the axle. Shaft pulleys are versatile and widely used in construction.

rope or belt

Ropes or pulleys are mechanical devices used to move large masses. The rope supports a large mass and can be moved easily by applying a force equal to one quarter of the mass to the loose end. Quad pulleys have four wheels and provide the mechanical advantage of four wheels. It is often used in factories and workshops. It is also a popular choice in the construction industry. If you are installing a pulley in your vehicle, be sure to follow these simple installation instructions.

First, you need to understand the basics of how a rope or pulley works. The machine consists of one or more wheels that rotate on an axle. The rope or belt is wrapped around the pulley and the force exerted on the rope is spread around the pulley. It then transfers the force from one end of the rope to the other. The pulley system also helps reduce the force required to lift objects.

Another common rope or pulley is the differential pulley. This is similar to a rope pulley, but consists of two pulleys of different radii. The tension in the two halves of the rope supports half the load that the live pulley should carry. These two different types of pulleys are often used together in composite pulley systems.

Mechanical advantage

The mechanical advantage is the ratio of the force used to move the load through the pulley system to the force applied. It has been used to measure the effectiveness of pulley systems, but it also requires assumptions about applied forces and weights. In a simple 1:1 pulley system, the weight lifting the weight is the same as the weight of the person pulling the weight. Adding mechanical advantage can help make up for the lack of manpower.

This advantage stems from the mechanical properties of simple machines. It requires less force and takes up less space and time to accomplish the same task. The same effect can also be achieved by applying less force at a distance. Furthermore, this effect is called the output force ratio. The basic working principle of a pulley system is a rope with a fixed point at one end. The movable pulley can be moved with very little force to achieve the desired effect.

The load can be moved through the vertical entry using a simple pulley system. It can use a simple “pulley block” system with a 2:1 “ladder frame” or a 4:1 with dual pulleys. This can be combined with another simple pulley system to create a compound pulley system. In this case, a simple pulley system is pulling another pulley, giving it a 9:1 mechanical advantage.

Commonly used

You’ve probably seen pulley systems in your kitchen or laundry room. You probably already use it to hang clothes on an adjustable clothesline. You may have seen motor pulleys in the kitchens of commercial buildings. You might even have seen one on a crane. These machines use a pulley system to help them lift heavy loads. The same goes for theaters. Some pulleys are attached to the sides of the stage, enabling the operator to move up and down the stage.

Pulley systems have many uses in the oil and petroleum industry. For example, in the oil and gas industry, pulley systems are used to lay cables. They are arranged in a pulley structure to provide mechanical energy. When the rope is running, two pulleys are hung on the derrick to facilitate smooth running. In these applications, pulleys are very effective in lifting heavy objects.

A pulley is a simple mechanical device that converts mechanical energy into motion. Unlike chains, pulleys are designed to transfer power from one location to another. The force required to lift an object with a pulley is the same as that required by hand. It takes the same amount of force to lift a bucket of water, but it’s more comfortable to pull sideways. A bucket of water weighs the same as when lifted vertically, so it’s easy to see how this mechanism can be useful.

Safety Notice

When using pulleys, you should take several safety precautions to keep your employees and other workers on the job site safe. In addition to wearing a hard hat, you should also wear gloves to protect your hands. Using pulleys can lead to a variety of injuries, so it’s important to keep these precautions in mind before using pulleys. Here are some of the most common:

Pulleys are an important piece of equipment to have on hand when lifting heavy objects. Pulleys not only reduce the force required to lift an object, but also the direction of the force. This is especially important if you are lifting heavy objects, such as a lawn mower or motorcycle. Before starting, it is important to make sure that the anchoring system can support the full weight of the object you are lifting.

When using a pulley system, make sure the anchor points are adequate to support the load. Check with the pulley manufacturer to determine the weight it can safely lift. If the load is too large, composite pulleys can be used instead. For vertical lifts, you should use a sprocket set and wear personal protective equipment. Safety precautions when using pulleys are critical to worker health and safety.

editor by czh 2022-12-20

China 15mm Thick Fire Resistant Conveyor Pulleys Coverage Pulley Rubber Strip Lagging pulley bearing

Product Description

15mm Thick Fire Resistant Conveyor Pulleys protection Pulley Rubber Strip Lagging

Merchandise Description

Rubber drum lagging is 1 variety of special rubber sheet which coated on conveyor pulley , roller , drum and so forth., so as to defend conveyor belt from slipping . It is widely employed in conveyor technique of coal ming, steel mill, energy plant, cement mill and many others.

The Pulley Lagging Rubber Sheet offered by CZPT arrive with CN Bonding Levels for much better adhesion levels as also with buffed surface. The profiled patterns on the top surface, in CZPT or square embossing increase belt grip and tracking on conveyors, while minimizing belt wear. The Pulley Lagging Rubber Sheet is accessible in different grades of rubber, such as FRAS and oil resistant grades.

Characteristics

- Diverse colours, durometers and thickness

- Large release and non adhere covers

- Influence and abrasion resistant

- Anti static high grip surfaces

- Low self lubricating

- Food and drug administration authorized materials

- Warmth resistant, ozone, UV, and chemical resistant

- Twin durometers / multi compositions

Apps

- Limited specs – precision ground

- Distinct textured surfaces

- Profiling / inHangZhou / crowning / grooving

- Sleeves / tube and strong bar shares

- Thermal forged – no splice or delaminating

- Non marking handles

Merchandise Parameters

|

Buy No. |

Pattern Type |

Dimensions ( T * W * L ) |

|

1 |

Diamond / Basic/herringbone |

8 * 2000 * ten thousand |

|

2 |

Diamond / Basic/herringbone |

10 * 2000 * 10000 |

|

3 |

Diamond / Basic/herringbone |

twelve * 2000 * 10000 |

|

four |

Diamond / Basic/herringbone |

fifteen * 2000 * 10000 |

|

5 |

Diamond / Basic/herringbone |

18 * 2000 * ten thousand |

|

Particular Gravity |

1.twenty five g/cm3 |

|

Hardness |

60 +/- 5 Shore A |

|

Tensile Energy |

150 kg / cm2 |

|

Elongation |

350% |

|

Abrasion |

one hundred twenty mm3 |

Certifications

Packaging & Shipping

Packaging Specifics

one. Common Package deal for CZPT delivery & air transport

2. Drinking water-evidence package

three. Deal Content: Plywood Circumstance / Wood box / Pallet

four. Unique packing requirements ought to be acknowledged in progress.

Port: ZheJiang HangZhou ZheJiang

Business Profile

ZheJiang CZPT Rubber Items Co., Ltd is a major specialist manufacturer of conveyor belts & conveyor add-ons in China. The principal workshops protect twenty,000 square meters in the whole 60,000 sq. meters of the plant. The applied technologies and equipment in the superior creation traces are point out of the art in the sector. The product sales headquarters is situated in the funds of China, ZheJiang with branches in domestic and abroad.

It specializes in following 3 series: 1) Hefty-responsibility Conveyor Belt, including common EP/NN and CC Belt, Chevron Belt, Oil Resistant Belt, Abrasion Resistant Belt, Heat Resistant Belt, Fire Resistant Belt, Chemical Resistant Belt, Sidewall Belt, Flat Transmission Belts, 2) Rubber Sheets, which includes SBR, NBR, NR, CR, EDPM, Rubber With Insertion 3) Conveyor accessories. These 3 collection of items conform to RMA, DIN, ASTM and ISO specs.

Its goods, honored with “The most Advanced amount of Merchandise” by the Committee of Science and Engineering, have been widely used in mining and quarrying, electricity stations, metal crops, bulk cargo terminals, cement industry, and other materials managing fields. With wonderful good results in domestic industry, it has been concentrating on global market with several hundreds of overseas valued clients in Asia, South The united states, North The usa, Africa and Europe.

The organization mission:

1.Source 1-end exceptional support to worldwide clients.

2. Have interaction in complete remedies with conveyor belting and energy transmission belting.

three. Persist in engineering enhancement and top quality manage in the entire method of production and service.

Application

These are appropriate for:

| Concrete plants | Recycling and mineral processing plants |

| Squander sorting & Compost machines | Metallic processing industry |

| Scrap recycling | Timber business |

| Sawmills | Excreta & sewage sludge conveying |

| Corn, rape and soilages conveying | Solvent extraction crops |

| Paper business |

You may possibly like:

| Material: | Rubber |

|---|---|

| Application: | Conveyor Pulley/Roller/Drum Lagging |

| Structure: | Black Rubber with Green Cn Layer |

| Thickness: | OEM |

| Certification: | ISO |

| Condition: | New |

###

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) |

|---|

###

|

Order No.

|

Pattern Type

|

Size ( T * W * L )

|

|

1

|

Diamond / Plain/herringbone

|

8 * 2000 * 10000

|

|

2

|

Diamond / Plain/herringbone

|

10 * 2000 * 10000

|

|

3

|

Diamond / Plain/herringbone

|

12 * 2000 * 10000

|

|

4

|

Diamond / Plain/herringbone

|

15 * 2000 * 10000

|

|

5

|

Diamond / Plain/herringbone

|

18 * 2000 * 10000

|

###

|

Specific Gravity

|

1.25 g/cm3

|

|

Hardness

|

60 +/- 5 Shore A

|

|

Tensile Strength

|

150 kg / cm2

|

|

Elongation

|

350%

|

|

Abrasion

|

120 mm3

|

###

| Concrete plants | Recycling and mineral processing plants |

| Waste sorting & Compost machines | Metal processing industry |

| Scrap recycling | Timber industry |

| Sawmills | Excreta & sewage sludge conveying |

| Corn, rape and soilages conveying | Solvent extraction plants |

| Paper industry |

| Material: | Rubber |

|---|---|

| Application: | Conveyor Pulley/Roller/Drum Lagging |

| Structure: | Black Rubber with Green Cn Layer |

| Thickness: | OEM |

| Certification: | ISO |

| Condition: | New |

###

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) |

|---|

###

|

Order No.

|

Pattern Type

|

Size ( T * W * L )

|

|

1

|

Diamond / Plain/herringbone

|

8 * 2000 * 10000

|

|

2

|

Diamond / Plain/herringbone

|

10 * 2000 * 10000

|

|

3

|

Diamond / Plain/herringbone

|

12 * 2000 * 10000

|

|

4

|

Diamond / Plain/herringbone

|

15 * 2000 * 10000

|

|

5

|

Diamond / Plain/herringbone

|

18 * 2000 * 10000

|

###

|

Specific Gravity

|

1.25 g/cm3

|

|

Hardness

|

60 +/- 5 Shore A

|

|

Tensile Strength

|

150 kg / cm2

|

|

Elongation

|

350%

|

|

Abrasion

|

120 mm3

|

###

| Concrete plants | Recycling and mineral processing plants |

| Waste sorting & Compost machines | Metal processing industry |

| Scrap recycling | Timber industry |

| Sawmills | Excreta & sewage sludge conveying |

| Corn, rape and soilages conveying | Solvent extraction plants |

| Paper industry |

Types of pulleys and their advantages and disadvantages

There are several types of pulleys. Learn the basic equations of the pulley system. Then learn about the different uses for pulleys. The disadvantages of using pulleys will be covered. Knowing these, you can buy the pulley that suits your needs. Here are some of the best pulley types and their pros and cons.

Basic equations of pulley systems

A pulley system is a mechanism that allows two blocks of a certain mass to be connected by a taut rope. The acceleration of each block is the same in magnitude and direction. The external force acting on each block is the weight of the block (10g) and the tension in the string. The tension between the two blocks is the total tension and the force acting on the pulley is the weight of the two blocks.

This simple mechanism uses two simple equations to explain how the system works. First, the mass of the weight on both sides of the pulley must be the same. When the weight is forced to move, the rope tightens and the second pulley descends. The weight is also attached to the second pulley and must be the same distance as the first pulley. This will result in a speed ratio of 2 times the distance covered by the first pulley.

Second, we have to calculate the force required to lift the object. The lower mass is supported by a wire configuration passing through all pulleys, while the uppermost pulley is used to apply the force. The lower block is used to support the weight. The applied force needs to travel a distance nx to move the weight. This distance, called MA, can be written as:

Once we have gathered the necessary information, we can apply the calculations to the pulley system. We can also use the Mechanical Advantage Calculator to calculate the force on the anchor. To do this, we must apply a force to the load as well as to the pulley itself. Using this equation, we can calculate the force required by the load to lift the load.

Types of pulleys

There are three basic types of pulleys: movable, fixed and compound. Both types of pulleys translate the force applied to them. The ideal mechanical advantage of pulleys is two. This is because a single movable pulley only doubles the force, whereas a compound pulley doubles or triples the force. This type of pulley is often used with other types of pulleys.

Movable pulls move with the weight of the load, and the force pulling them increases on the lift side. They are often found in utility elevators and construction cranes. These systems are very simple, inexpensive and quiet to use. The force required to lift the object depends on the mechanical advantage of the system. The two most common types of pulleys are listed below. Let’s take a closer look at each one.

V-shaped pulleys are used in vehicles and electric motors. These pulleys require a “V” belt to function properly. Some have multiple “V” grooves to avoid slipping. They are used in heavy duty applications to reduce the risk of power slip. These pulleys also have more than one “V” groove. V-belt pulleys are commonly used in vehicles and electric motors.

Composite pulleys are made from more than one type of cable or rope wrapped around the wheel. They can be fixed or hinged and are usually made of stainless steel or bronze. Composite pulleys have multiple layers and can be a single unit or many different components. There are three main types of pulleys: fixed pulleys and composite pulleys. These are the most common types. Almost every type of pulley is used for some type of application.

Fixed pulleys have one advantage over movable pulleys: they change direction as the weight of the load increases. They are typically used in heavy construction equipment. Gun tackles, patio tackles, and stationary tackles are examples of equipment that use a pulley mechanism. These devices are very common and can be found on most modern construction sites. They provide great convenience for lifting large loads.

application

What are the applications of pulleys? Simply put, a pulley is a mechanical device that transforms a difficult task into an easier one. It consists of ropes and pulleys. It is usually used to lift objects. Usually, people wrap a rope around a pulley and pull up to lift the object. One disadvantage of using pulleys is that they require the same force as lifting the object directly.

One of the most popular applications of pulleys is lifting heavy objects. They help people pull up heavy objects and blocks. The system can also be used in seeders, lifts, grinders, etc. Other applications include raising flags, loading cargo, pulling curtains and rock or mountain climbing. Students can learn about the various uses of pulleys and the physics behind them.

Pulleys can be made of many different materials, depending on the application. Some are movable, which means they move with the object they are used to lift. This pulley system can be made of nylon, wire rope or fiber material. The best part about these systems is that they are easy to install and maintain. For a better grasp, use the guide or video tutorial to learn more about the pulley system and how it works.

Tapered pulleys are common in paper mills. They are high-quality pulleys that transmit power to connected parts. They can be dynamic or static and have different balances. Because pulley systems are highly customized, most industrial applications require systems designed specifically for specific applications. In this way, the system is safe, simple and inexpensive. The benefits of this design are endless.

The most common use of pulleys is for motor drives. They are used to minimize noise by applying force to the shaft to reduce the workload. They are also less expensive than gears and do not require lubrication. Furthermore, they can change the direction of the applied force. They are also less expensive than gears and are often used with other components. A screw is a cylindrical member with helical ribs used to connect something.

shortcoming

Although the pulley system makes it easier to move heavy objects, it still has some drawbacks. When using a pulley system, you must remember that the force required to lift the weight increases with the number of cycles. In addition, the distance between the puller and the heavy object increases, which may lead to accidents. Also, moving heavy objects can be tricky if the rope slips. Pulley systems are not very expensive and can be easily assembled. However, it does require a lot of space.

First, it is not efficient. Besides being inefficient, pulleys produce different forces at different speeds. Fixed pulleys use more force than the load, while movable pulleys move with the load. A movable pulley requires less force than a fixed pulley, but the combined system travels a long distance. Therefore, this method is not as efficient as the fixed method.

Pulleys are not only used in industrial processes. You can see them in various places in your daily life. For example, large construction cranes use pulleys to lift heavy loads. Even flagpoles, blinds, clotheslines, ziplines, motors and climbing equipment use pulleys. Still, despite their advantages, the disadvantages are not too serious.

Another disadvantage of the pulley is its wear and tear. While a pulley’s housing is theoretically infinite, its bearings and locking components typically wear out over time. To overcome this problem, a new bearing and locking assembly can be installed. No need to replace the housing and shaft, the entire assembly can be re-bonded and painted to replicate the original look. Alternatively, the pulley can be replaced with a new housing and shaft.

Using pulleys can also reduce the advantage of pulleys. On the other hand, interception and tackle is a system in which two pulleys are connected to each other using ropes. Unlike pulleys, pulley pulley systems can be adjusted in the direction of travel and can move heavy loads up to four times their force when used in hydraulic lifts.

editor by czh 2022-11-30

China wholesaler China CZPT Manufacturer Good Quality Rubber Arc Toothed Drive and Pulleys Belts on Sale with Free Design Custom

Product Description

China Tiger manufacturer good quality rubber arc toothed drive and pulleys belts on sale

Product:HTD 8M

Technical datas:

| Arc tooth Rubber timing belt | ||||

| Series | Type | Pitch | Tooth height | Belt thickness |

| (mm) | (mm) | (mm) | ||

| HTD | 2M | 2 | 0.75 | 1.36 |

| 3M | 3 | 1.17 | 2.4 | |

| 5M | 5 | 2.06 | 3.8 | |

| 8M | 8 | 3.36 | 6 | |

| 14M | 14 | 6.02 | 10 | |

| 20M | 20 | 8.4 | 13.2 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 2.2 | |

| S4.5M | 4.5 | 1.17 | 2.81 | |

| S5M | 5 | 1.91 | 3.4 | |

| S8M | 8 | 3.05 | 5.3 | |

| S14M | 14 | 5.3 | 10.2 | |

| RPP/HPPD | P2M | 2 | 0.76 | 1.36 |

| P3M | 3 | 1.15 | 1.9 | |

| P5M | 5 | 1.95 | 3.5 | |

| P8M | 8 | 3.2 | 5.5 | |

| P14M | 14 | 6 | 10 | |

WHY CHOOSE US-Expert support of over 10 years belting experience.

QUALITY ASSURANCE

Guarantee that the commodity hereof complies in all respects with the quality and specification stipulated in the contract.

DELIVERY GUARANTEE

Ship the goods within the shipment time from the port of shipment to the destination in the contract.

FACTORY PRICE

Prices refer to the cost of raw materials directly from factory.

TEAM OF PROFESSIONALS

Offer experienced customer service and technical support including belts selection, calculation, application and after-sale service.

FABRICATION WORKSHOP

Provide belts cutting, jointing, as well as belt perforations, belt sealed, belt coated with rubber and sponge, belt guides,etc.

SERVICE NETWORK

Set up office, branches in HangZhou, HangZhou, HangZhou, Hongkong, etc, service locations for processing industrial belts in HangZhou,HangZhou,Yongbo etc.

Our partners:

Processings:

Application:

Shipping:

| Shipping method | Load port |

| DHL,FEDEX,UPS,TNT | — |

| By Air | HangZhou,HangZhou,ZheJiang port |

| By sea | HangZhou,HangZhou,ZheJiang port |

Payment methods:

| Terms | Bank charges | Remark |

| 100% T/T advance payment | 30-100USD | For new customers and regular customer of less than 5000USD order amount |

| 50% T/T advance payment and balance before shipping | 60-200USD | Regular customers and new customer of 5000-15000USD order amount |

| 30% T/T advance payment and balance before shipping | 60-200USD | Regular customers of over 15000USD order amount |

| Western Union | 15-40USD | – |

| Moneygram | 8-25USD | – |

Exhibitions,training&activeties:

Certifications:

Other related products:

-Flat power transmission belts

-Light-Weight fabric conveyor belts

-High temperature fiber glass belt

-V- belts

-PU round belts

-Fabrication machines

Tgrbelt:Passion for belting solutions always!!!

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.